Shenzhen Jinghe Technology Co., Ltd. (JHIMS) has empowered clients globally over the past five months with top-tier automation solutions. Our recent project with a Russian LED lighting manufacturer showcases our expertise in enhancing SMT assembly efficiency using our innovative lens vibrating feeder. Explore how we turned challenges into success.

Industry: LED Lighting

Challenge: The client struggled with manual lens assembly for LED panel light bars, causing a 40% efficiency bottleneck and unmet demand.

Solution: We integrated our lens vibrating feeder with their Hanwha SM481 pick and place machines, automating lens placement. This boosted throughput by 35% and ensured consistent quality.

Results: Production efficiency soared, with downtime reduced by 25%. The client praised the seamless integration: "JHIMS’s feeder transformed our workflow—no issues, just results."

Our lens vibrating feeder is engineered for precision in SMT assembly. Key specs include:

This design ensures seamless integration and boosts SMT efficiency across various production lines.

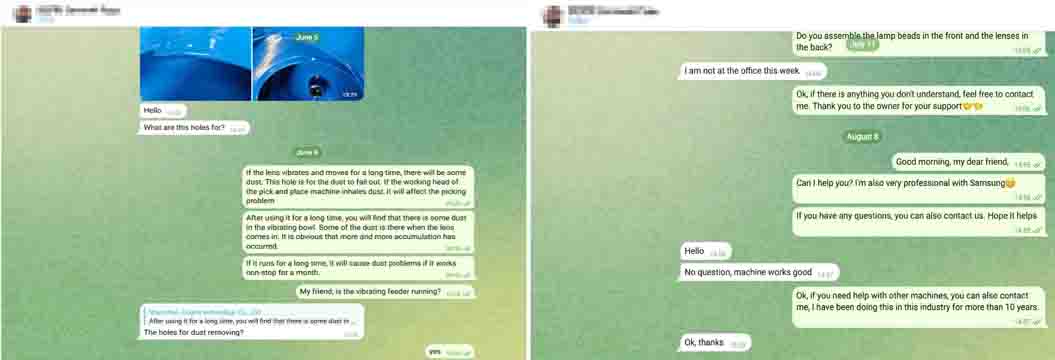

Check out unedited photos and videos of our lens vibrating feeder in action:

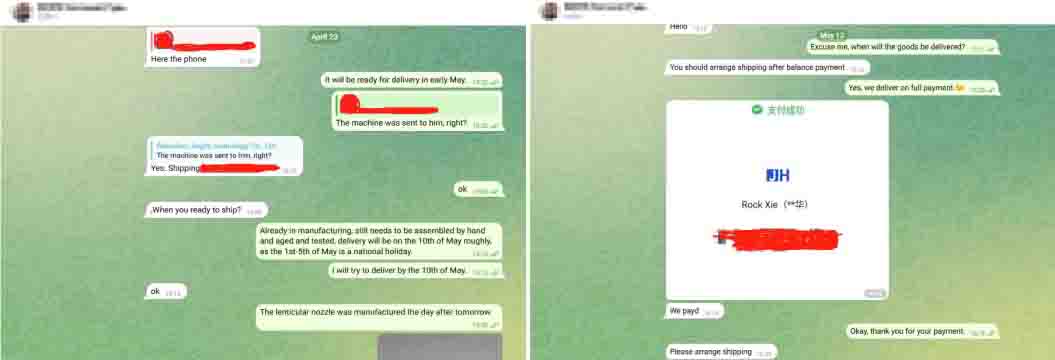

Customer feedback highlights satisfaction with performance:

Watch our 5-channel feeder work with Hanwha SM481 and DECAN S1 machines:

A production manager from the Russian client shared: "The lens vibrating feeder not only increased our SMT efficiency by 35%, but its reliability has saved us countless hours in maintenance. JHIMS delivered beyond expectations."

Reach out at: +8618975335491 (WhatsApp, Telegram, Skype)

Explore similar success stories:

Interested? Let’s optimize your production line—contact us now!

Our vibratory feeders streamline SMT assembly with precision and speed. Designed for LED lenses, they support multiple pick-and-place machines (e.g., Hanwha SM481, DECAN S1), handling various shapes via adjustable frequencies. Built with durable materials, they thrive in tough conditions, cutting labor costs by 30%.

What machines are compatible? Hanwha SM481, DECAN S1, and more.

How much efficiency improves? Up to 35%, based on client data.

Is customization available? Yes, tailored to your needs.