A leading manufacturer from Ningbo, specializing in PCBA OEM and LED lighting products, partnered with JHIMS to overcome production challenges. Over the past two years, JHIMS has empowered numerous clients with high-quality SMT solutions, earning trust through professionalism and reliability. This case study showcases our expertise in integrating a custom lens feeder with the Hanwha SM481 SMT pick-and-place machine for advanced LED lens assembly.

Customer Industry: PCBA OEM and LED lighting products

Demands and Challenges: The Ningbo customer received a large order for LED panel light bars but lacked experience with lens vibratory feeders and LED manufacturing. Their Hanwha SM481 machines required upgrades to handle precise lens assembly efficiently.

Solution:

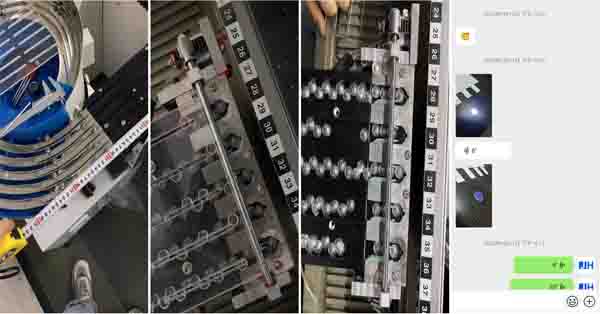

The custom lens feeder for the Hanwha SM481 features a 5-channel vibration system, allowing simultaneous pickup by 5 work heads. This design reduces assembly time by 25% compared to standard feeders. The feeder supports lens sizes from 10mm to 15mm, with a precision tolerance of ±0.1mm, making it ideal for high-volume LED lens assembly solutions.

The Ningbo customer praised JHIMS for delivering a reliable SMT lens feeder solution. "JHIMS transformed our production line," said their operations manager. The upgraded Hanwha SM481 system increased production efficiency by 30%, as shown in on-site photos and videos. The feeder’s compatibility with multiple lens sizes and replacement of lost optics ensured seamless operations.

The Hanwha SM481 lens vibration feeder enhances throughput with its multi-channel design, a breakthrough in automatic assembly.

Explore lens feeders for other SMT machines:

Ready to optimize your Hanwha SM481 with a custom lens feeder? Contact JHIMS at +8618975335491 (WhatsApp, Telegram, Skype) or visit our website for cutting-edge SMT solutions.

More case studies:

Shenzhen Jinghe Technology Co., Ltd. © 2025