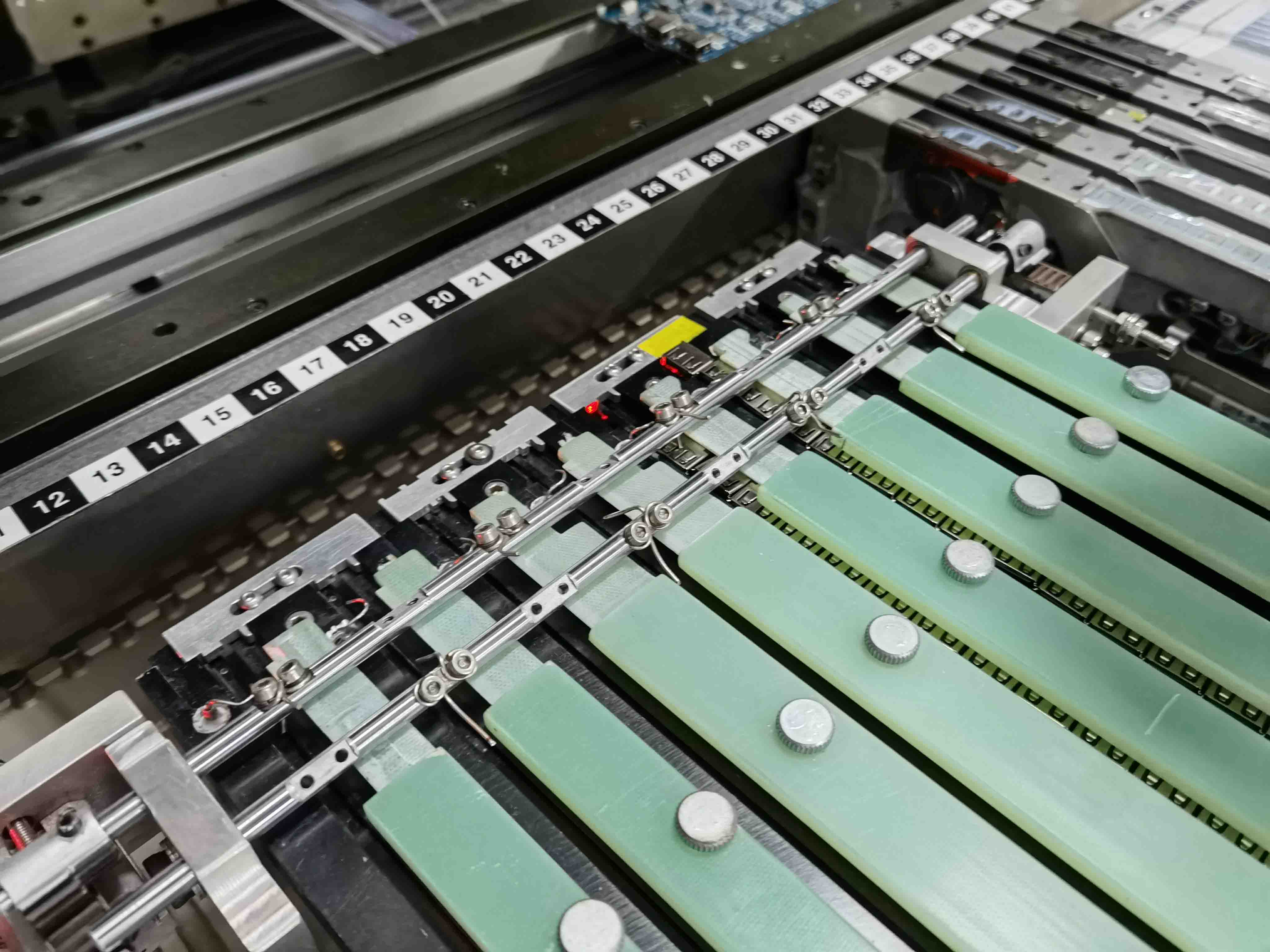

JHIMS USB Vibrating Feeder: Cost Savings in SMT Assembly

Background

A Shenzhen-based manufacturer of mobile power products faced high costs due to various USB components in their SMT assembly lines. Traditional USB reel braiding was costly, prompting them to adopt JHIMS’s USB Vibrating Feeder for an efficient, cost-effective solution.

Project Challenges and Solutions

Challenges

-

High costs from USB reel braiding for multiple USB types.

-

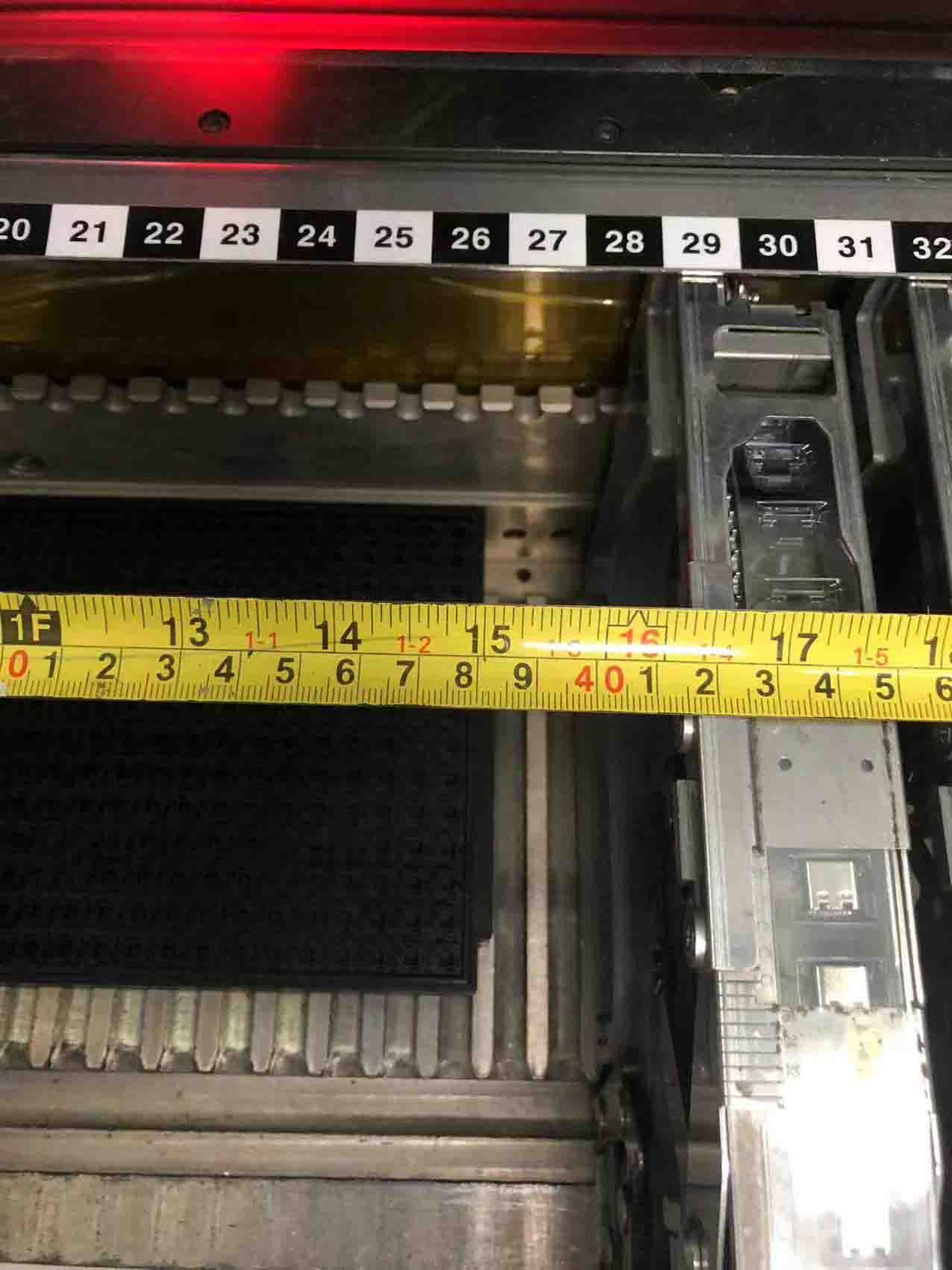

Need for a feeder matching SM481 machine speed without excessive space.

-

Reliable feeding without jamming, tested over one month.

Solutions

-

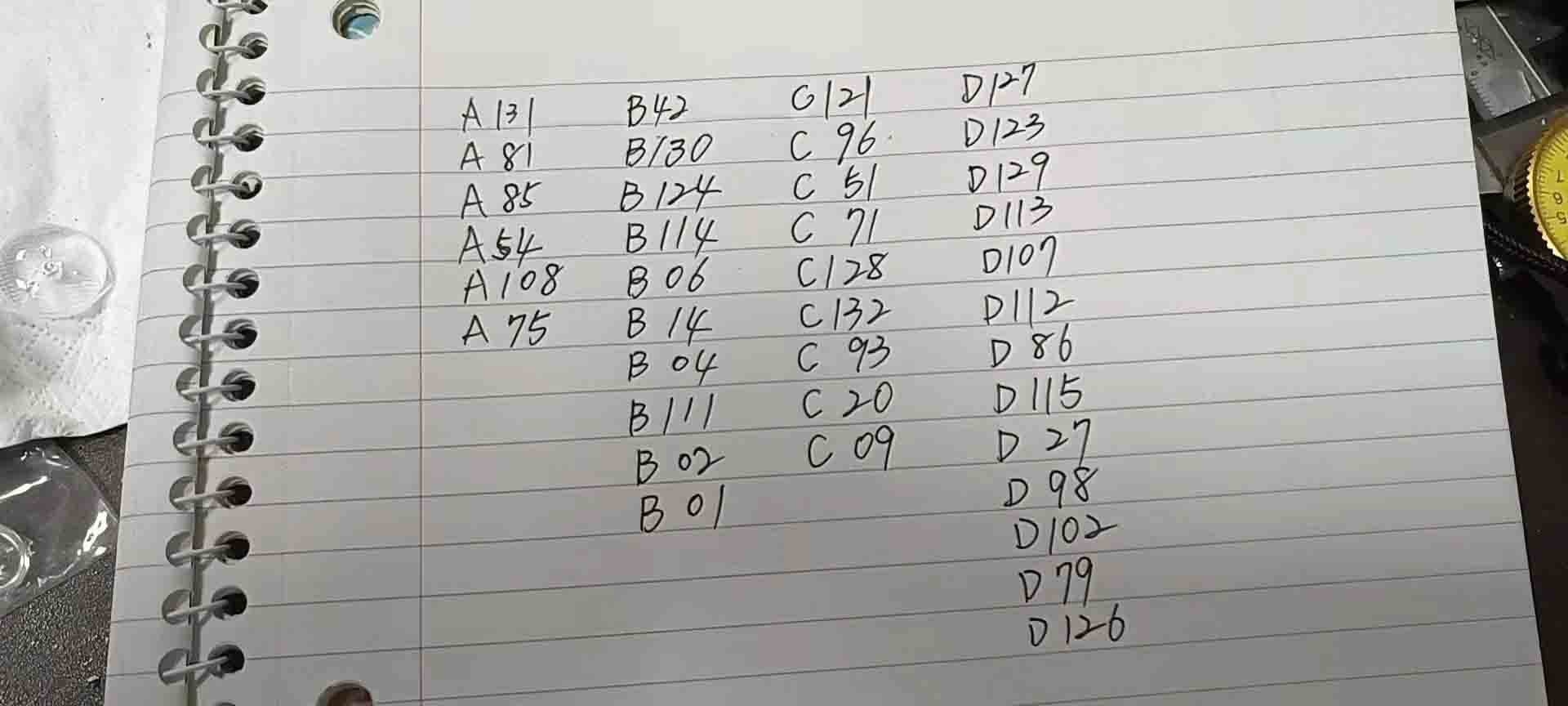

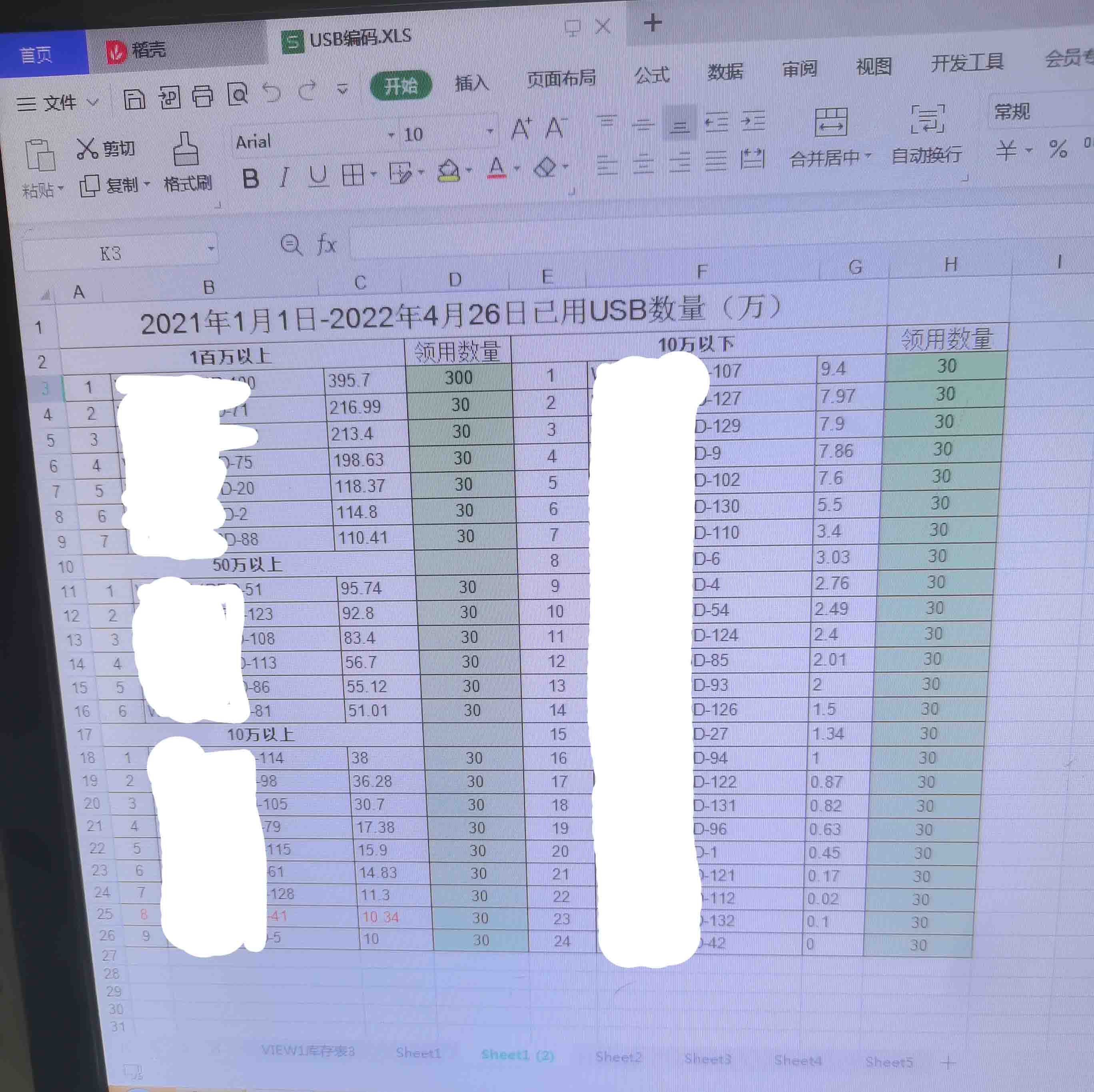

Categorized 45 USB types into 4 channel routes for efficient feeding.

-

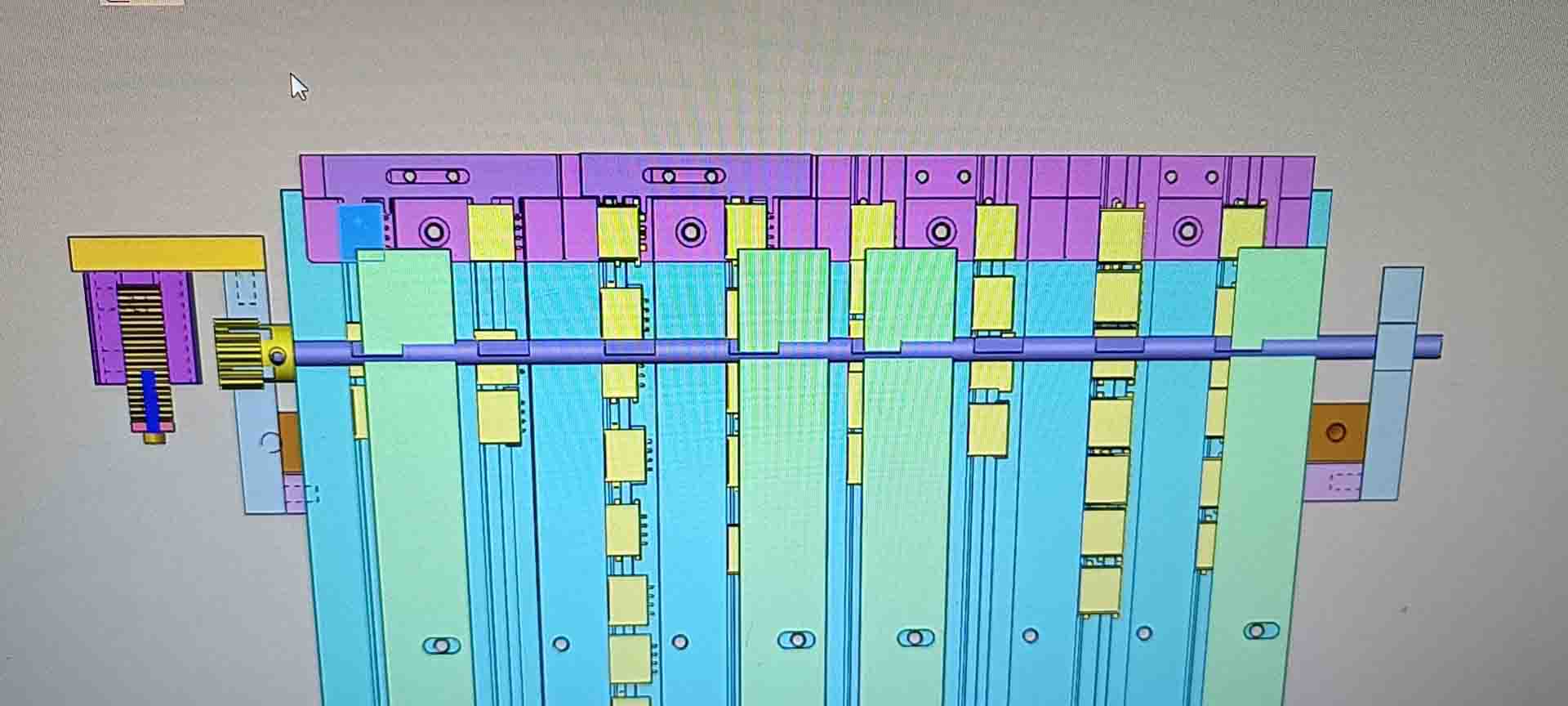

Designed an 8-channel system with 4 vibrators for SM481 speed.

-

Used a compact front-and-rear bowl design to save space.

-

Added anti-jamming features and optimized bowl routes.

Specific Results

The JHIMS USB Vibrating Feeder delivered significant savings:

|

Time Period |

Cost Savings (RMB) |

|

Daily |

400 |

|

Monthly |

11,200 |

|

Yearly |

134,400 |

Investment was recovered in under a year, proving its cost-effectiveness.

Why Choose JHIMS?

-

Reliability: High-quality products delivered on time.

-

Professionalism: Deep expertise for optimal solutions.

-

Experience: Over 10 years of customized solutions.

-

Support: From design to after-sales service.

-

Cost-Effectiveness: Competitive pricing with quality.

-

Transparency: Feedback via YouTube.

FAQs

How does the JHIMS USB Vibrating Feeder reduce costs?

By replacing expensive USB reel braiding with a reusable feeder, the JHIMS USB Vibrating Feeder significantly cuts down on material costs, offering savings of up to 134,400 RMB annually.

What types of USB components are supported?

The feeder supports 45 different types of USB components, categorized into 4 channel routes for efficient feeding.

Contact Us

Contact us at +8618975335491 (WhatsApp, Telegram, Skype) to optimize your SMT assembly today!

More Case Studies