The Indian customer, a leading enterprise in electrical parts and accessories manufacturing, faced significant challenges in assembling a large number of screws efficiently. Their existing manual screwdrivers resulted in slow assembly speeds, making it difficult to meet tight delivery deadlines. To address this, they chose Shenzhen Jinghe Technology Co., Ltd. (JHIMS) and our advanced handheld automatic screw tightening machine solution.

The customer needed to significantly increase their screw assembly speed to meet growing demand and tight delivery schedules. Manual screwdrivers were not only slow but also labor-intensive, leading to worker fatigue and inconsistent quality. The challenge was to find a solution that could automate the process, reduce assembly time, and maintain high precision in screw fastening.

JHIMS provided a comprehensive solution featuring our state-of-the-art handheld automatic screw tightening machine paired with an automatic screw feeder system. This system automates the screw feeding process, eliminating the need for manual screw placement and reducing unnecessary personnel movements. Key features include:

After implementing JHIMS's handheld automatic screw tightening machine, the customer experienced remarkable improvements:

"JHIMS’s solution cut our assembly time in half, revolutionizing our production line." - Indian Manufacturer Lead

Our handheld automatic screw tightening machine utilizes advanced torque control systems and automatic screw feeding mechanisms to ensure precise and efficient fastening. This makes it one of the best handheld screw tightening tools for high-volume production, reducing operator fatigue and improving assembly speed.

| Feature | Specification |

|---|---|

| Screw Size | M1-M6 |

| Torque Range | 0.5-5 Nm |

| Speed | Up to 60 screws/min |

While this case study focuses on electrical parts manufacturing, our handheld automatic screw tightening machine is also widely used in industries such as automotive, electronics, and furniture assembly, where speed and precision are critical. Explore more case studies.

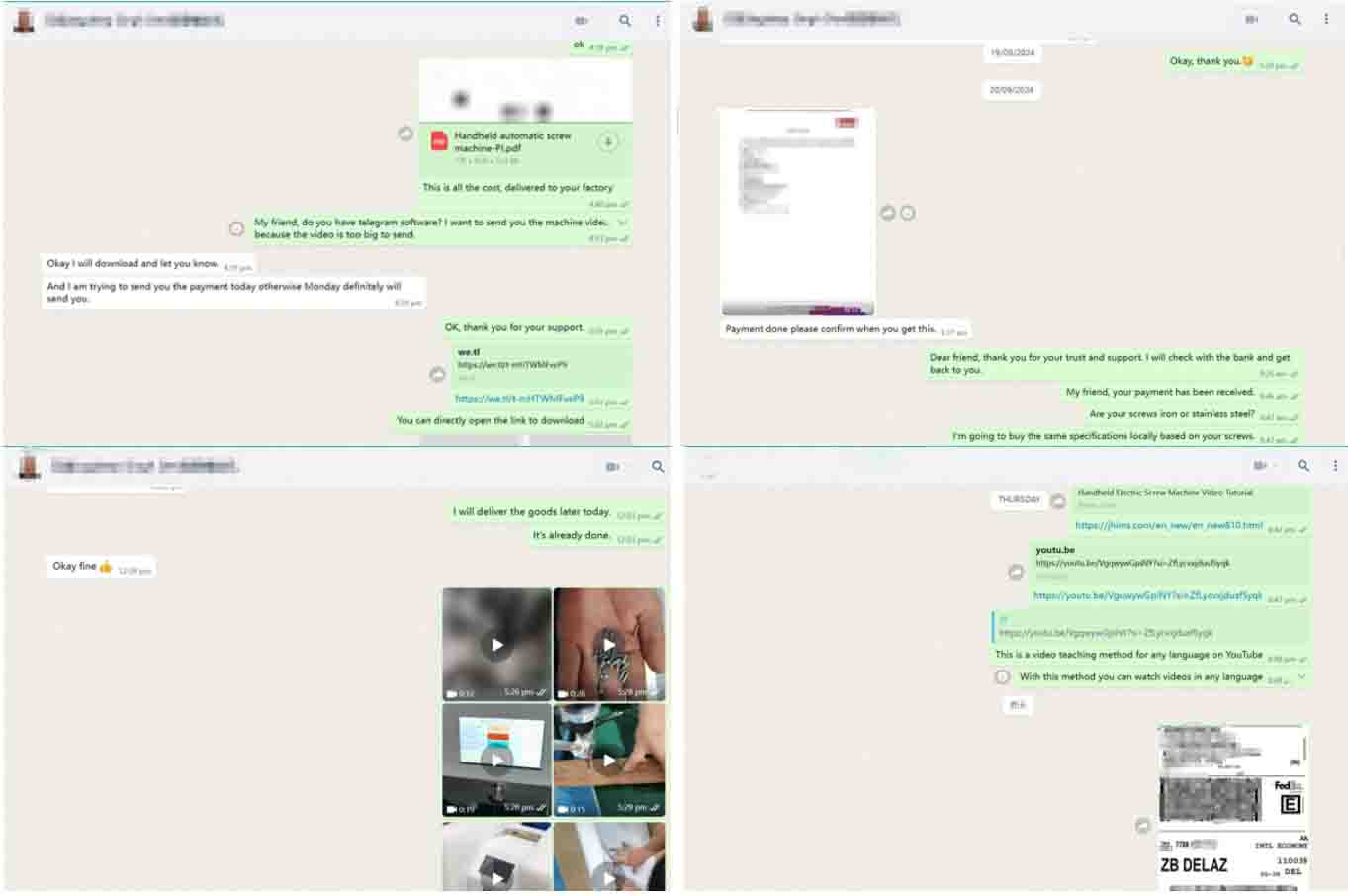

Below is an image showcasing the handheld screw fastening machine in action, demonstrating its ease of use and efficiency.

Watch the video below to see the stark difference between a regular screwdriver and our handheld automatic screwdriver in terms of speed and efficiency.

See our handheld automatic screwdriver in action, showcasing its features and benefits.

Learn how to use our handheld automatic screwdriver with this step-by-step teaching demonstration.

The machine automates the screw feeding and tightening process. Screws are automatically supplied to the screwdriver, which then fastens them with precise torque control, significantly reducing assembly time and effort.

Benefits include faster assembly speeds, reduced worker fatigue, consistent quality, and improved overall production efficiency.

Yes, our machine is compatible with various screw sizes, typically ranging from M1 to M6, making it versatile for different applications.

Our handheld automatic screw tightening machine is ideal for electronics due to its precision torque control and compatibility with small screws (M1-M6).

Contact us at +8618975335491 (WhatsApp, Telegram, Skype) to discuss how we can help you achieve your manufacturing goals. Whether you have questions or are ready to explore our products, we're here to assist you.