Product Number:JH-D350

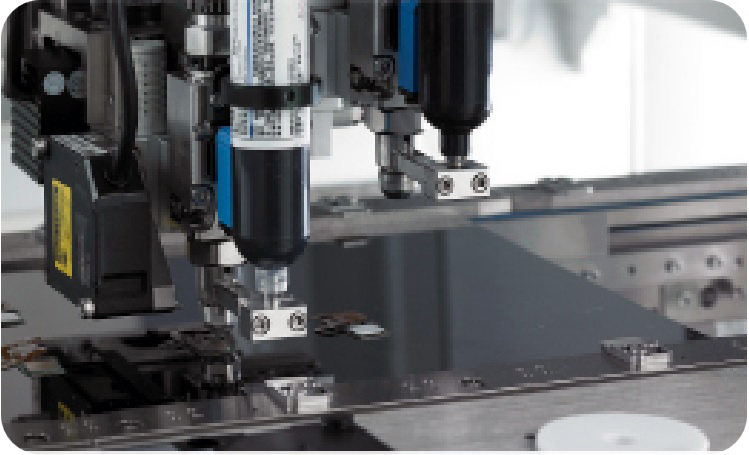

Product Usage:Dispensers are used to precisely apply liquid materials, such as glue or coatings, to specific locations during the manufacturing process.

Applicable Industries:Glue dispensing machines are widely used in electronics, automobiles, medical devices, home appliances, LED lighting, packaging and handicrafts industries.

National Advisory Hotline:

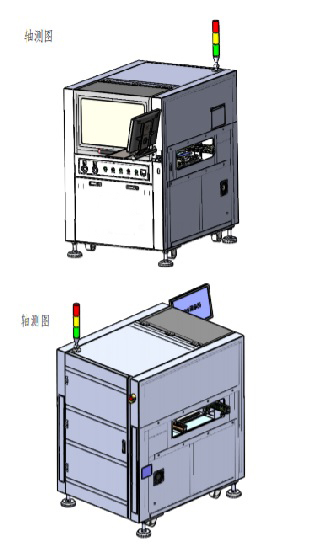

+86 18975335491Elevate your precision manufacturing with the JHIMS JH-D350, a state-of-the-art non-contact epoxy resin dispensing machine engineered for high-speed, high-accuracy applications in electronics assembly, semiconductor packaging, and medical device production. Optimized for 2025 Industry 4.0 trends, it delivers unmatched performance in jet dispensing systems.

The JH-D350 introduces a modular architecture, separating control and servo modules for rapid fault diagnosis and minimal downtime. Its non-contact jetting technology eliminates Z-axis movement, ensuring damage-free dispensing and uniform epoxy application, ideal for high-precision dispensing machines in electronics.

Explore our dispensing accessories for tailored enhancements.

Unlike conventional systems, the JH-D350 achieves up to 200 points/second jetting, reducing cycle times by 40% and minimizing material waste. Its AI-driven viscosity compensation adapts to material changes in real-time, setting a new standard for reliability in electronics assembly dispensers.

Compare with our DS300 Micro Dispensing Machine for smaller-scale applications; JH-D350 excels in larger ranges and higher speeds.

Designed for high-stakes sectors, the JH-D350 supports cutting-edge applications like 5G component assembly and bio-medical innovations, delivering precision coating and potting for advanced manufacturing.

Ready out-of-the-box with essential components, the JH-D350 ensures quick setup and maximum productivity in jet dispensing systems.

With AI-optimized processes, the JH-D350 delivers adaptive dispensing for complex patterns, outperforming traditional machines in precision and efficiency.

| Item | Design Advantage |

|---|---|

| 1 | Flying dispensing for straight, horseshoe, spiral, and arc patterns |

| 2 | Constant temperature valve control for consistent process quality |

| 3 | Automatic height correction for precise part detection |

| 4 | AI-driven process division with glue amount alarms |

| 5 | Direct import of patch files and visual programming |

| 6 | 0.02mm repeatability with high-precision screws |

| 7 | 500kg steel frame for ultra-stable, low-vibration operation |

| 8 | High-performance servo for fast response and positioning |

| 9 | 0.005mg glue accuracy with jet valve integration |

| 10 | Up to 200 points/s jetting, 56,000 points/h in flight mode |

| 11 | Fully automatic track adjustment for flexibility |

Optimized for 2025 manufacturing demands, the JH-D350 offers energy-efficient performance and robust specifications for high-precision applications.

| Item | Parameter | Value |

|---|---|---|

| 0 | Model | JH-D350 |

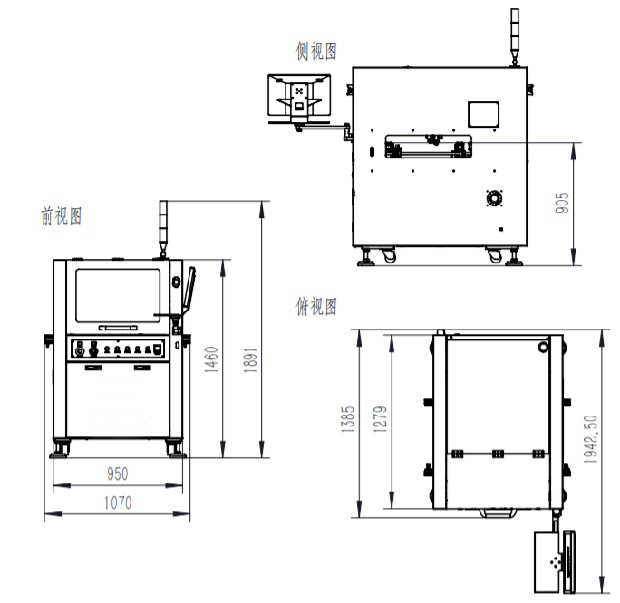

| 1 | Dimensions (L*W*H) | 770x1280x1420 mm |

| 2 | Weight | 500 kg |

| 3 | Control Method | PC + Motion Card |

| 4 | Software | Windows + JR AD |

| 5 | Programming | Teaching + CAD Map + Picture File |

| 6 | Drive Mode | Servo Motor + Ball Screw |

| 7 | Number of Axes | X/Y/Z |

| 8 | Max Movement Speed | 1000 mm/s |

| 9 | Max Dispensing Range (LxW) | 500x450 mm |

| 10 | Component Height | 50 mm |

| 11 | Repeatability | ±0.01 mm |

| 12 | Track Drive | Stepper Motor + Stepper Driver |

| 13 | Track Modulation | Automatic / Manual |

| 14 | Track AM Speed | 800 mm/min |

| 15 | Track Working Height | 920 ±20 mm |

| 16 | Orbit Transfer Speed | 0-6 m/min |

| 17 | Orbit Transfer Direction | L-R / R-L |

| 18 | Number of Tracks | 1 |

| 19 | Track AM Range | 80-450 mm |

| 20 | Belt Conveyor Weight | Standard 3kg (Customizable) |

| 21 | PCB Edge Space | Standard 5mm (Optional 3mm) |

| 22 | Socket Port | SMEMA |

| 23 | Screw Valve Tilt | 0°/35° (Optional) |

| 24 | Screw Valve Rotation | ±180° |

| 25 | Valve Body | Injection/Piezoelectric Valve (Choose One) |

| 26 | Air Pressure Requirements | 0.4-0.6 MPa |

| 27 | External Feeding System | Optional |

| 28 | Screw Valve Configuration | Optional |

| 29 | Barcode Scanning | Optional |

| 30 | Track Preheating Zone | Optional |

| 31 | Rail Work Area Heating | Optional |

| 32 | Glue Calibration System | Optional |

| 33 | UPS Configuration | Optional |

| 34 | Laser Altimeter System | Optional |

| 35 | CCD Vision System | Optional |

| 36 | A Dispensing Length | 350 mm |

| 37 | Two Dispensing Lengths | - |

| 38 | Power Supply | 200-240VAC 50-60Hz |

| 39 | Safety Standard | CE |

Backed by over a decade of expertise and ISO 9001 certification, JHIMS delivers the JH-D350 as a future-proof solution for high-precision dispensing. Its AI-adaptive technology reduces costs by 30% compared to competitors, ensuring sustainability and efficiency.

Testimonial: "The JH-D350 boosted our semiconductor line efficiency by 40% with flawless precision." – Leading Electronics Manufacturer

Compared to Nordson EFD, the JH-D350 offers higher jetting speed (200p/s vs. 150p/s) at a lower cost. Against Scheugenpflug, its modular design ensures easier maintenance, reducing downtime by 25%.

Learn how JH-D350 outperforms in our comparison guide.

Watch our demo: JH-D350 Precision Dispensing in Action (contact us for full video access).

Visit our full FAQ page for more details.

© 2025 Shenzhen Jinghe Technology Co., Ltd(JHIMS) Precision Engineering. All rights reserved. About JHIMS | Contact Us