Product Number:CNJET-D series

Product Usage:The glue dispensing and inspection machine is mainly used to accurately apply glue on the automated production line and detect the dispensing quality in real time to ensure the consistency and reliability of the product.

Applicable Industries:Dispensing and inspection machines are widely used in industries such as electronics manufacturing, automotive industry, medical equipment, LED lighting and consumer electronics to improve production efficiency and product quality.

National Advisory Hotline:

+86 18975335491The CNJET-D series revolutionizes adhesive dispensing with piezoelectric jetting and AI-driven visual inspection, delivering 80%+ efficiency gains for electronics, automotive, and medical manufacturing.

The CNJET-D integrates high-speed piezoelectric jetting with real-time 2D/3D visual inspection, ensuring defect-free bonding, sealing, and encapsulation. Its digital control system supports complex applications, reducing waste by 50%+ compared to manual methods.

Unlike competitors, our system offers proprietary SPZT9900 valves and MES integration for Industry 4.0, enabling unmanned production lines with full traceability.

.jpg)

Our dual-valve system supports synchronous and asynchronous dispensing, increasing throughput by 80%+. Independent XY calibration ensures ±0.01mm accuracy for batch production.

Explore our dual-valve innovations for more details.

.jpg)

The SPZT9900 valve offers ±90° rotation and 0-45° tilt, solving issues like glue offset and surface contamination. This flexibility is ideal for multi-angle electronics assembly.

Learn how this outperforms traditional methods in our technical guide.

.jpg)

Single, dual, or segmented tracks reduce downtime and support mixed-model production, enhancing equipment utilization across batch sizes.

Discover track options in our configuration overview.

.jpg)

With 800 points/second and 0.2mm dot accuracy, this valve handles 0-200,000 Cps fluids. Its modular design and non-contact jetting minimize downtime and bubbles.

.jpg)

Our proprietary system adapts to diverse scenarios with multi-calibration and Bad Mark recognition, ensuring high reliability. Data management supports intelligent manufacturing.

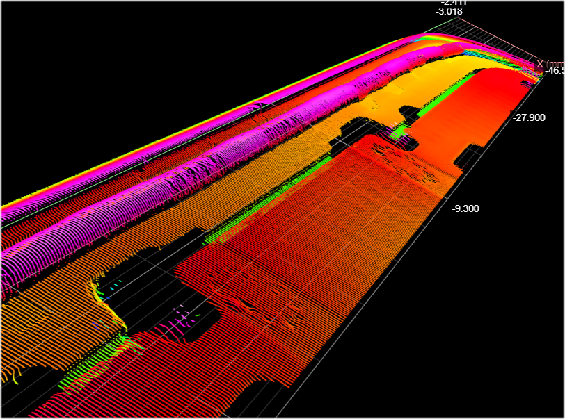

Automated 2D/3D inspection detects leaks, breaks, and dimensions, enabling unmanned lines with AI-driven defect classification.

Seamless MES connectivity ensures traceability with material ID management, auto-program calls, and predictive maintenance.

A leading smartphone manufacturer adopted the CNJET-D for underfill dispensing, reducing defects by 60% and increasing throughput by 75%. The AI inspection system caught micro-leaks missed by manual checks, saving $200,000 annually.

Read more success stories.

| Feature | CNJET-D | Competitor A | Competitor B |

|---|---|---|---|

| Dispensing Speed | 800 points/sec | 600 points/sec | 700 points/sec |

| Accuracy | ±0.01mm | ±0.05mm | ±0.03mm |

| Inspection | 2D/3D AI | 2D only | Manual |

| MES Integration | Full | Partial | None |

Our system outperforms in speed, accuracy, and smart integration, offering superior ROI.

| Feature | Details |

|---|---|

| Dispensing Speed | Up to 800 points/second |

| Accuracy | 0.2mm dot; ±0.01mm repeatability |

| Viscosity Range | 0-200,000 Cps |

| Inspection | 2D/3D with AI defect classification |

| Valve Types | Piezoelectric, dual synchronous/asynchronous |

| Tilt/Rotation | 0-45° tilt; ±90° rotation |

| Power | 220V-240V |

| Certifications | CE, RoHS |

Reduces waste by 50%+ and supports custom solutions. See applications.

Contact us for pricing, demos, or customizations.