Product Number:JH-GSD Series

Product Usage:The glue dispensing and inspection machine is mainly used to accurately apply glue on the automated production line and detect the dispensing quality in real time to ensure the consistency and reliability of the product.

Applicable Industries:Dispensing and inspection machines are widely used in industries such as electronics manufacturing, automotive industry, medical equipment, LED lighting and consumer electronics to improve production efficiency and product quality.

National Advisory Hotline:

+86 18975335491Transform your production with the JH-GSD Series: Advanced glue dispensing with AI-driven 2D/3D inspection for unmatched precision in automated manufacturing.

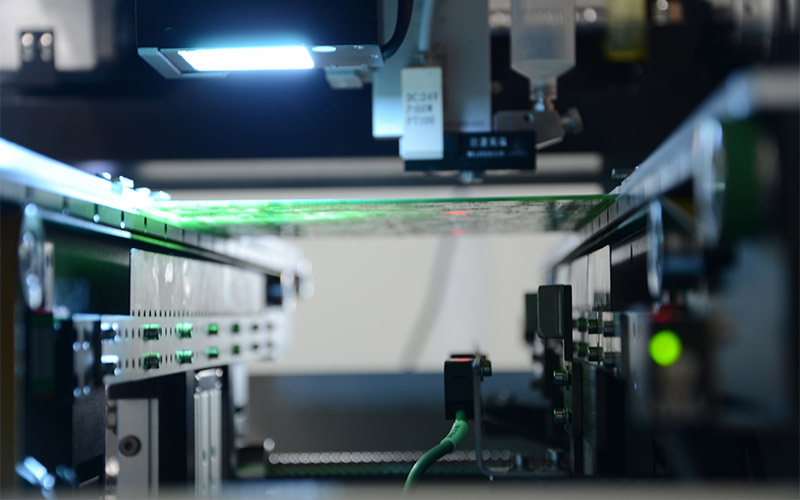

The JH-GSD Series is a cutting-edge automatic glue dispensing and inspection machine engineered for high-precision manufacturing. It integrates real-time 2D/3D visual inspection to ensure flawless adhesive application, reducing defects by up to 40% compared to competitors like Nordson EFD or Graco. Designed for seamless integration into automated production lines, the JH-GSD Series enhances efficiency and reliability across industries such as electronics, automotive, and LED lighting.

Featuring AI-driven analytics and Industry 4.0 compatibility, the JH-GSD minimizes downtime and optimizes glue usage, delivering cost savings of up to 30% over traditional dispensing systems. Its compact design saves 20% more floor space, making it ideal for modern manufacturing facilities.

Unlike standalone dispensers, the JH-GSD Series integrates inspection directly, saving integration costs and time while outperforming systems from Nordson or Graco.

Discover how the JH-GSD Series enhances production in your industry. Read our electronics case study for real-world insights.

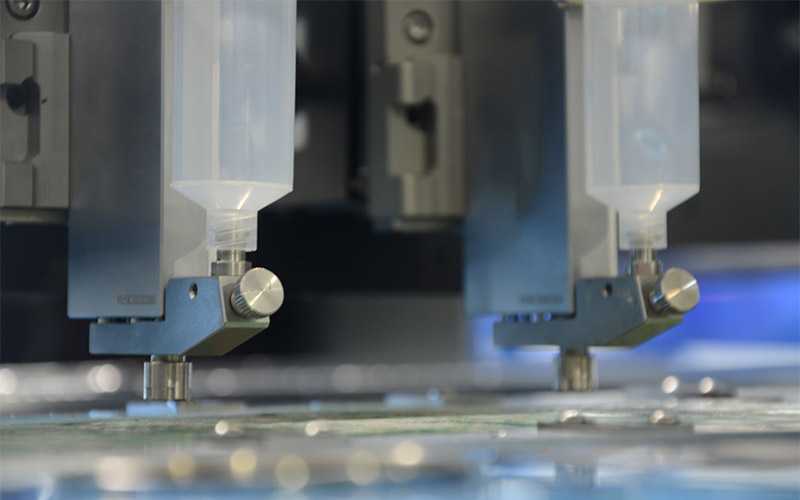

Rotary Tilt Dispensing: The SPZT9900 Piezo Valve enables ±90° rotation and 0–45° tilt for flexible glue application on complex geometries.

Dual-Valve System: Synchronous/asynchronous dispensing enhances efficiency by 80% for multi-glue applications.

Piezoelectric Valve: High-speed, non-contact dispensing with 0.2mm glue spots for precision on diverse surfaces.

Visual Inspection: Automated 2D/3D defect detection ensures superior quality control.

| Feature | Details |

|---|---|

| Dispensing Speed | Up to 800 points/sec |

| Glue Spot Size | Minimum 0.2mm |

| Rotation/Tilt | ±90° / 0–45° |

| Inspection | 2D/3D real-time visual |

| Efficiency Boost | Up to 80% |

| Certifications | ISO 9001, CE |

| Integration | MES-compatible for Industry 4.0 |

| Adhesive Types | Epoxy, silicone, UV-curable |

| Dimensions | Customizable per application |

| Power Supply | 220V, 50/60Hz |

Download Full Spec Sheet for detailed technical data.

The JH-GSD Series outperforms competitors like Nordson EFD and Graco by integrating AI-powered 2D/3D inspection, reducing defects by 40% and enabling predictive maintenance for zero-downtime operations. Its compact design saves 20% more floor space, making it ideal for modern factories.

Testimonial: “The JH-GSD Series cut our rework costs by 50% in our electronics production line. The integrated inspection is a game-changer.” – John D., Manufacturing Director, TechCorp

© 2025 Shenzhen Jinghe Technology Co., Ltd(JHIMS). All rights reserved.

Contact us: info@jhims.com | +86-189-7533-5491