Updated: October 15, 2023

Shenzhen Jinghe Technology Co., Ltd. (JHIMS) empowered an Indian OEM to boost production efficiency by 20% and reduce defects by 15% with our advanced AOI PCB Inspection Machine. This case study showcases how our solutions address the unique challenges of India PCB manufacturing.

An Indian OEM in the PCB manufacturing sector upgraded their production line with JHIMS’s high-precision printers and PCB inspection machines. Facing increased demand, they needed to enhance quality control and prevent defective products from reaching clients. Our Automated Optical Inspection (AOI) system was the perfect solution. For more on industry standards, visit IPC.

The client needed to replace manual inspections with a high-precision AOI system capable of handling complex PCB designs while integrating seamlessly into their workflow.

The Indian OEM reported significant improvements, including a 20% increase in production speed and a 15% reduction in defective PCBs. These results underscore the value of our AOI systems in ensuring top-quality output for India’s growing electronics market.

Our commitment to client success extends beyond delivery with industry-leading after-sales support:

An AOI PCB Inspection Machine uses automated optical technology to detect defects in printed circuit boards, ensuring high precision and efficiency in quality control.

JHIMS offers proven success, tailored solutions, and exceptional support for Indian manufacturers, backed by advanced technology and a deep understanding of local market needs.

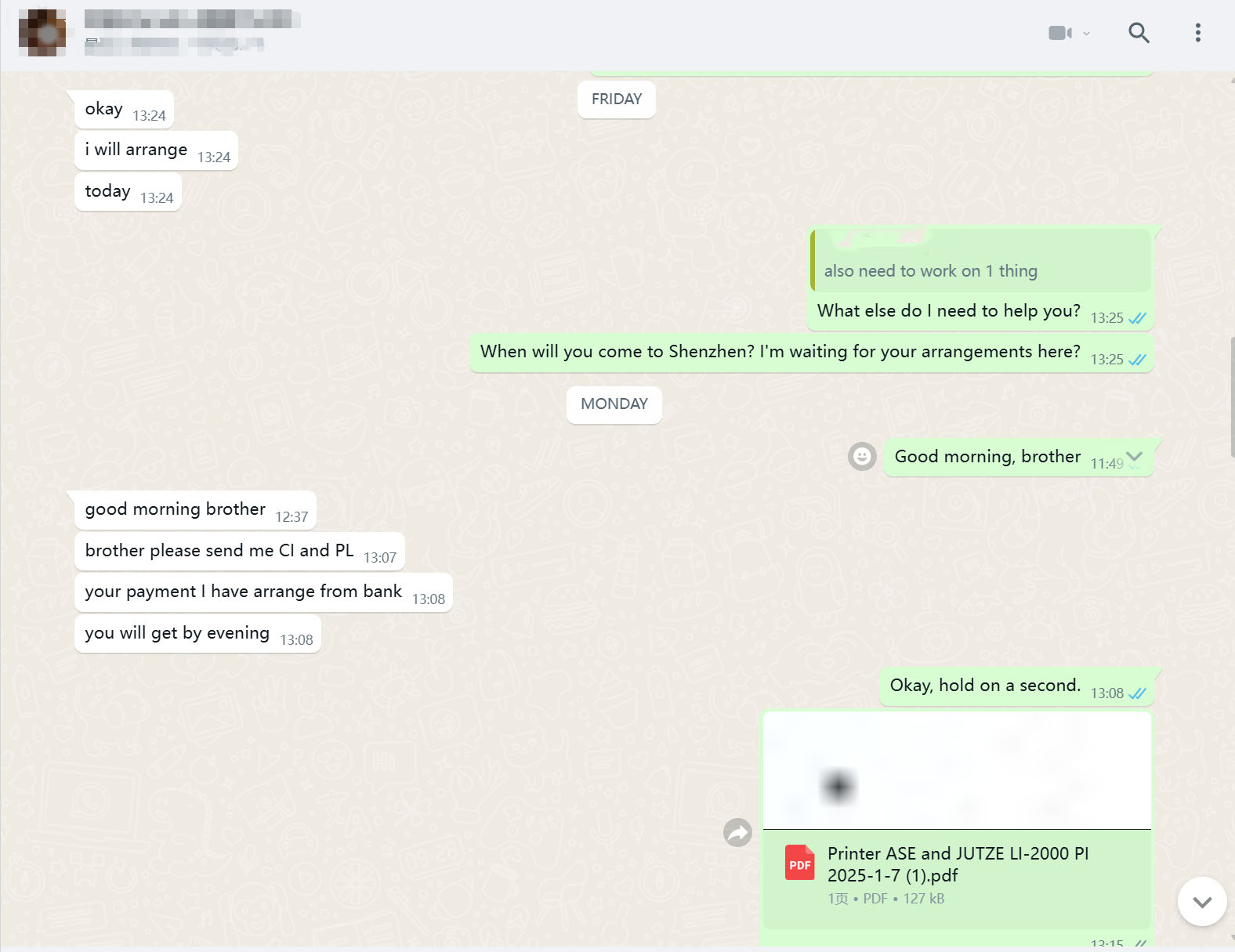

Reach out at +8618975335491 (WhatsApp, Telegram, Skype) to explore how our AOI PCB inspection machines can elevate your production.

Check out other success stories:

Contact us today to discuss your PCB inspection needs and join our growing list of satisfied clients!