An Indian OEM specializing in plug-in assemblies for electronics manufacturing faced significant challenges in streamlining their production process, particularly in cutting capacitor and resistor leads efficiently. With India’s electronics sector growing rapidly, driven by a demand for high-quality PCB assembly components, the OEM needed an advanced solution to stay competitive.

The client handled a wide variety of radial components, including THT DIP capacitors and resistors, requiring precise cutting to meet stringent specifications. Their outdated manual processes were labor-intensive, error-prone, and slow, while their existing machine struggled with diverse component sizes, leading to production bottlenecks and missed deadlines.

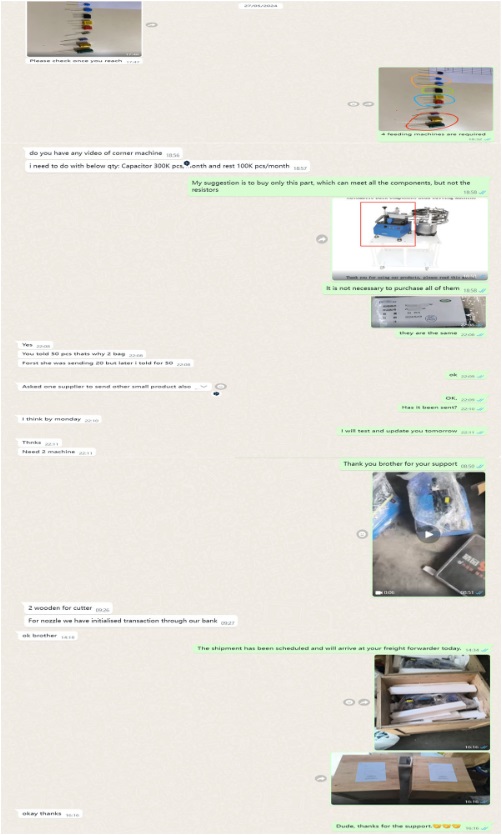

JHIMS delivered two DPJ-25 capacitor lead cutting machines. These machines, designed for radial components, feature high-speed vibration feeders, adjustable cutting lengths (3-25mm), and a precision cutting mechanism capable of processing up to 60 components per minute. One machine enhanced the existing line, while the second supported a new production line for scalability.

The implementation took three weeks, with JHIMS’s team providing on-site installation, calibration, and training. The machines were fine-tuned for components like capacitors with lead diameters of 0.4-1.0mm. Post-implementation, manual cutting was eliminated, reducing processing time by 25%, increasing throughput by 30%, and achieving 99% cut accuracy. This enabled the OEM to meet rising demand and expand their market share.

“JHIMS’s DPJ-25 machines transformed our production line. The precision, speed, and reliability are unmatched, and their team’s support made the transition seamless.” – OEM Manufacturing Manager

Watch the machine in action:

Learn to operate it with our instructional video.

Explore more JHIMS products.

Download our free PCB assembly efficiency guide or contact us at +8618975335491 or jhims.com.

Share this case study:

LinkedIn | Twitter | Facebook