In January 2023, a Russian OEM manufacturer faced significant challenges with their outdated AOI machine, which was unable to handle 0201 chip inspection or detect critical soldering defects such as false soldering and warping. These issues led to defective products reaching clients, resulting in complaints. After evaluating various solutions, the customer selected JHIMS’s advanced RGBW color light source AOI inspection machine for its high-precision PCB inspection capabilities and proven reliability in detecting even the smallest components and defects.

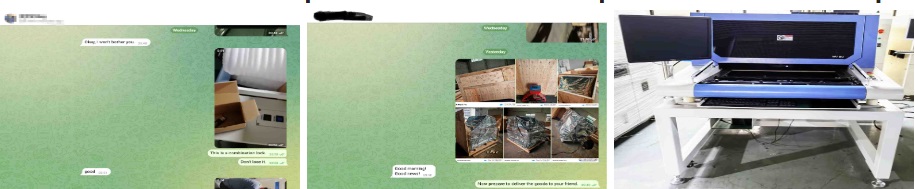

Below are images showcasing the JHIMS AOI inspection machine in operation and its preparation for shipment to the Russian customer.

Unlike competitors such as Nordson and Koh Young, JHIMS offers a cost-effective AOI inspection machine without compromising on quality. Our machine features an advanced RGBW 6-segment light source and dual backup systems, ensuring superior soldering defect detection and data security at a more competitive price point. This makes JHIMS the ideal choice for OEM manufacturers seeking high-precision inspection solutions without the premium cost.

“The JHIMS AOI inspection machine has transformed our PCB inspection process. We’ve seen a 50% reduction in defects and a significant improvement in production efficiency. Their team provided exceptional support throughout the implementation.” – Production Manager, Russian OEM

An Automated Optical Inspection (AOI) machine is a critical tool in electronics manufacturing, used to automatically inspect PCBs for defects such as soldering issues, component misplacements, and other quality concerns. It ensures high precision and efficiency in the production process.

0201 chips are extremely small, making them difficult to inspect with standard AOI machines. JHIMS’s advanced technology, including a high-resolution 13.4µ camera and RGBW light source, overcomes this challenge by providing the precision needed for accurate detection.

JHIMS’s AOI machine uses a 10-megapixel camera, RGBW 6-segment light source, and sophisticated software algorithms to detect even the smallest defects, such as soldering issues on IC pins. This ensures that all potential problems are identified before products reach customers.

Looking for a reliable, high-precision AOI inspection machine for your PCB manufacturing needs? Contact JHIMS today to discuss how we can tailor a solution for your business.

Address: JHIMS Technology, Shenzhen, China

Phone: +8618975335491 (Whatsapp, Telegram, Skype)

Explore Our AOI Products | Watch JHIMS on YouTube

Explore more success stories from JHIMS customers around the world: