LED Display Production Line: Automated Solutions for Efficiency

Transform your manufacturing with JHIMS's cutting-edge LED display production line solutions. Designed for high-throughput factories, our automated systems deliver precision, speed, and cost savings—perfect for producing LED modules and screens at scale.

Benefits of an Automated LED Display Production Line

Automation revolutionizes LED module manufacturing by minimizing errors and maximizing output. Achieve up to 120,000 components per hour (CPH) while reducing labor costs by 30%. Our solutions ensure consistent quality for indoor, outdoor, and fine-pitch displays, backed by rigorous testing. Ideal for industries like digital signage and virtual production.

Step-by-Step LED Screen Manufacturing Process

Our automated LED screen assembly line follows a streamlined workflow:

- Material Preparation: Source high-quality PCBs, SMD LEDs, and IC drivers. Dehumidify to prevent defects.

- Front-End SMT Assembly: Automated printing, placement, and reflow soldering for precise bonding.

- Back-End Processing: Apply protective coatings, potting, and curing for durability (e.g., IP65 rating).

- Assembly and Testing: Non-screw fastening for fine-pitch modules, followed by aging tests and visual inspections.

- Final Quality Control: Measure LED pull-force (>5N) and temperature profiles for reliability.

This process supports customizable pixel pitches from 1.5mm to 10mm.

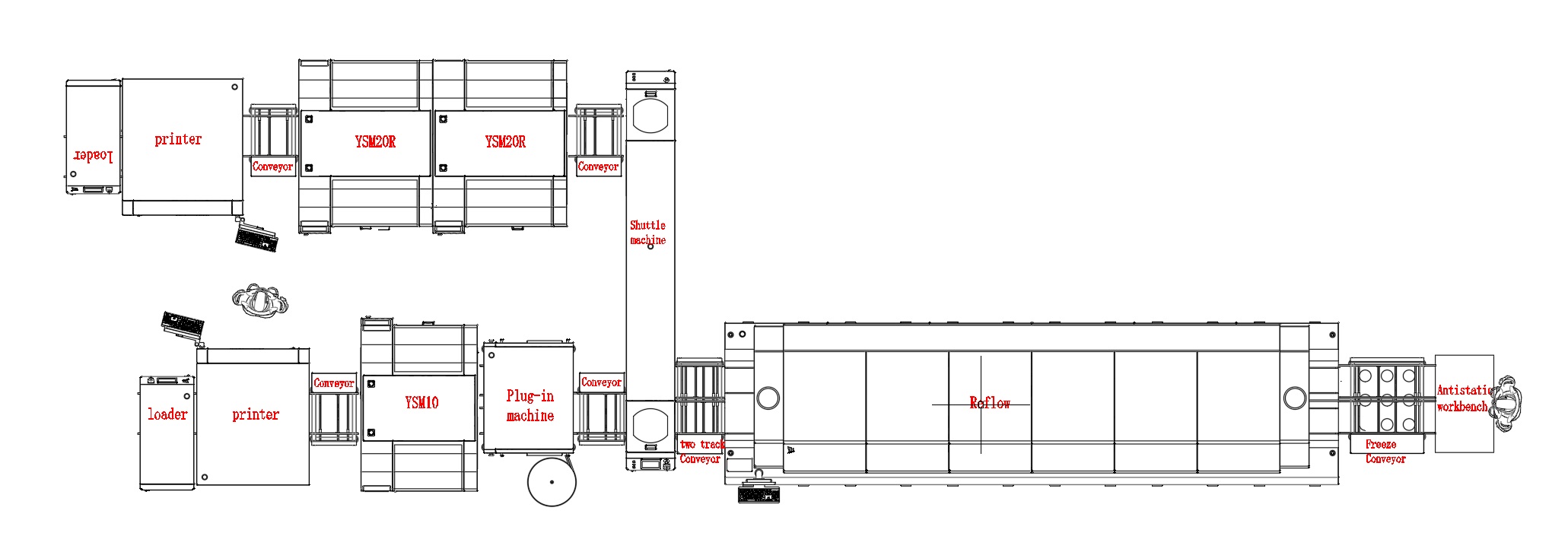

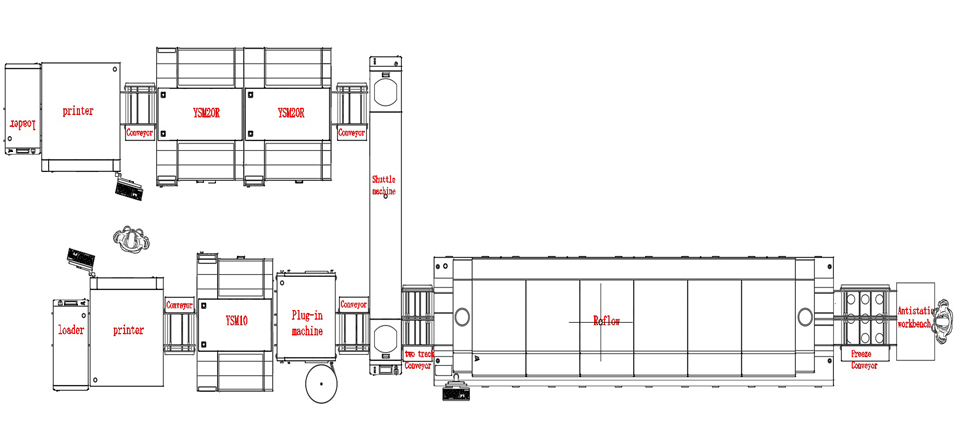

Equipment Specifications and Layout

Optimize your factory with our recommended setup. Below is a comparison of key equipment:

| Equipment Type | Capacity | Key Features | Estimated Cost (USD) |

|---|---|---|---|

| Pick-and-Place Machine | 120,000 CPH | High-speed, dual-lane for panels and boards | 50,000 - 100,000 |

| Reflow Oven | 8-10 zones | Precise temperature control (up to 260°C) | 20,000 - 40,000 |

| Potting Machine | 500 modules/hr | Automated silicone application | 15,000 - 30,000 |

| UV Curing Unit | 1,000 units/hr | Infrared/UV hybrid for fast drying | 5,000 - 10,000 |

Layout tip: Maintain 10mm spacing between units for stability. Total line footprint: ~50m² for full automation.

Industry Use Cases

- Outdoor Advertising: Weatherproof LED screens for billboards, as seen in Dubai installations with 1,200m² coverage.

- Events and Stages: Rental LED displays for concerts, like those used in Beijing Olympics.

- Virtual Production: Fine-pitch modules for XR studios, enabling real-time rendering. Learn more about our GOB LED solutions

Embedded Video: Watch the Process in Action

FAQ

- What is the typical throughput of an LED display production line?

- Up to 120,000 CPH for efficient scaling.

- How does automation reduce costs in LED module manufacturing?

- By cutting labor by 30% and minimizing defects through precision tech.

- What pixel pitches do you support?

- From 1.5mm (fine-pitch) to 10mm for various applications.

- Is training provided for the production line?

- Yes, including on-site setup and operational guidance.

Download Resources

Download LED Production Manual (PDF) for detailed specs and setup guides.

Get Started Today

Ready to upgrade your factory? Contact us for a custom quote or schedule a demo.

Messenger

Messenger

whatsapp

whatsapp

telegram

telegram