Shenzhen Jinghe Technology Co., Ltd. (JHIMS) delivers turnkey LED display module production lines, featuring seamless SMT LED assembly for models P1.25 to P3.91, with full automation to cut costs by 30% and boost output.

Integrate front-end SMT processes with back-end curing and testing for scalable LED display solutions. Achieve 114,000 CPH placement speeds and reliable quality for global markets.

Front-end dual setup: 13.92 modules/hour for P2.5 (14.25 sqm/20-hour shift). Back-end: 1125 pieces/day. Use formula: Modules = (CPH / LEDs per Module) × 0.95 efficiency.

View full catalog at JHIMS equipment.

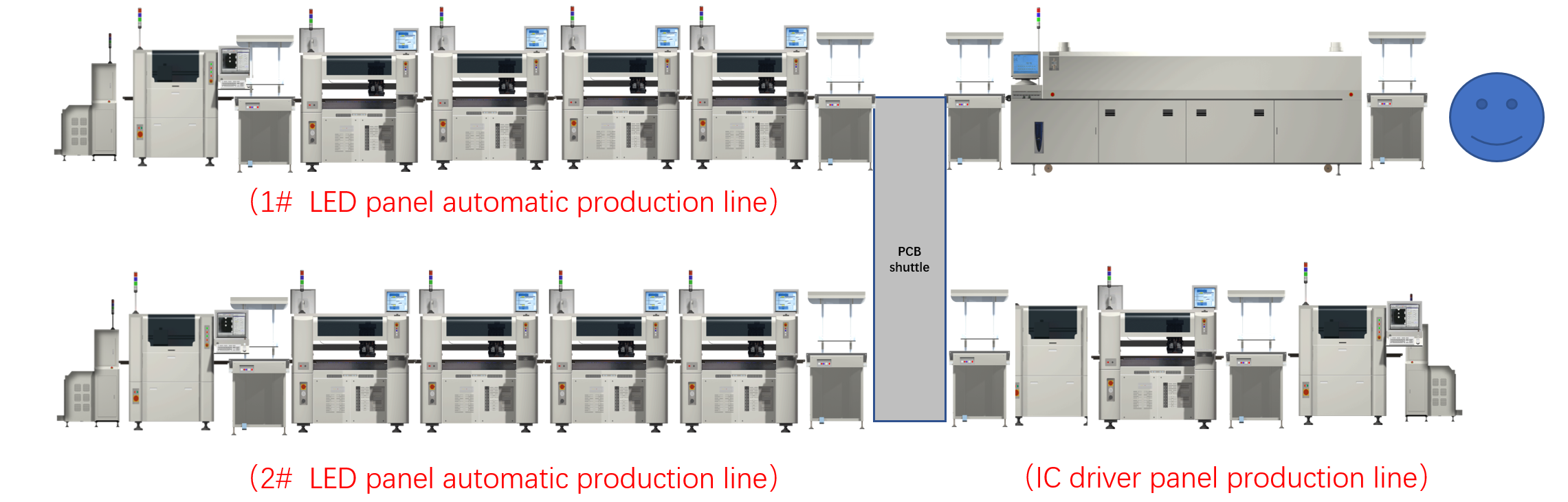

Front-end: 10m x 2m span, 10mm machine gaps, 40KVA power. Back-end: Linear flow for optimal throughput.

| Feature | JHIMS | *** LED | ***T |

|---|---|---|---|

| CPH Speed | 114,000 | 100,000 | 120,000 |

| Automation | Full (Front-Back) | Partial | Full |

| Cost Savings | 30% | 25% | 28% |

| Supported Models | P1.25-P3.91 | P1-P10 | P1-P5 |

Stadium Screens: 30% faster deployment for events. Retail Displays: Durable for 24/7 use, integrated with signage systems.

It involves SMT assembly, reflow soldering, selective glue application, curing, screw fastening, drying, and final testing for high precision.

Front-end achieves 114,000 CPH; back-end supports 1125 modules daily with 30% cost savings.

Yes, fully customizable for resolutions like P1.25-P3.91 and applications from signage to stadiums.

Includes Yamaha YSM40R for placement (114,000 CPH), HG5 printers, and BL26/3 dispensers.

Submit the form below for a free consultation and custom quote.

Interested in high-precision LED production? Contact JHIMS today for tailored solutions. We reply within 24 hours.