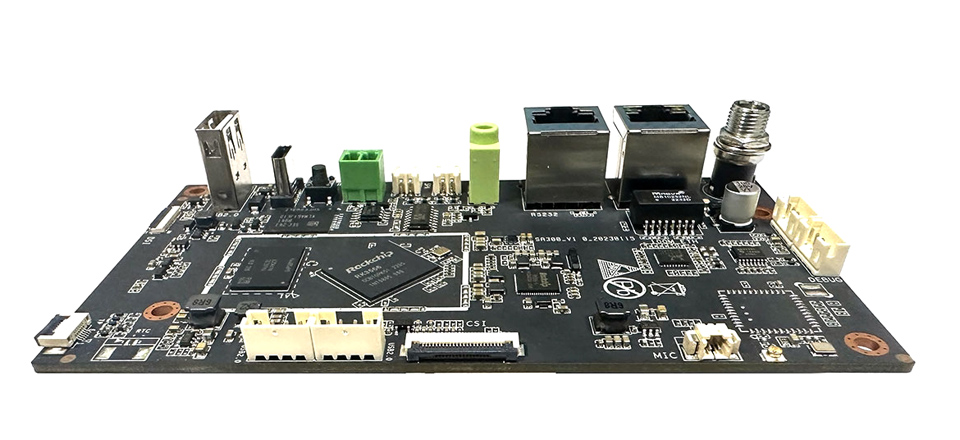

Advanced PCBA Manufacturing Services

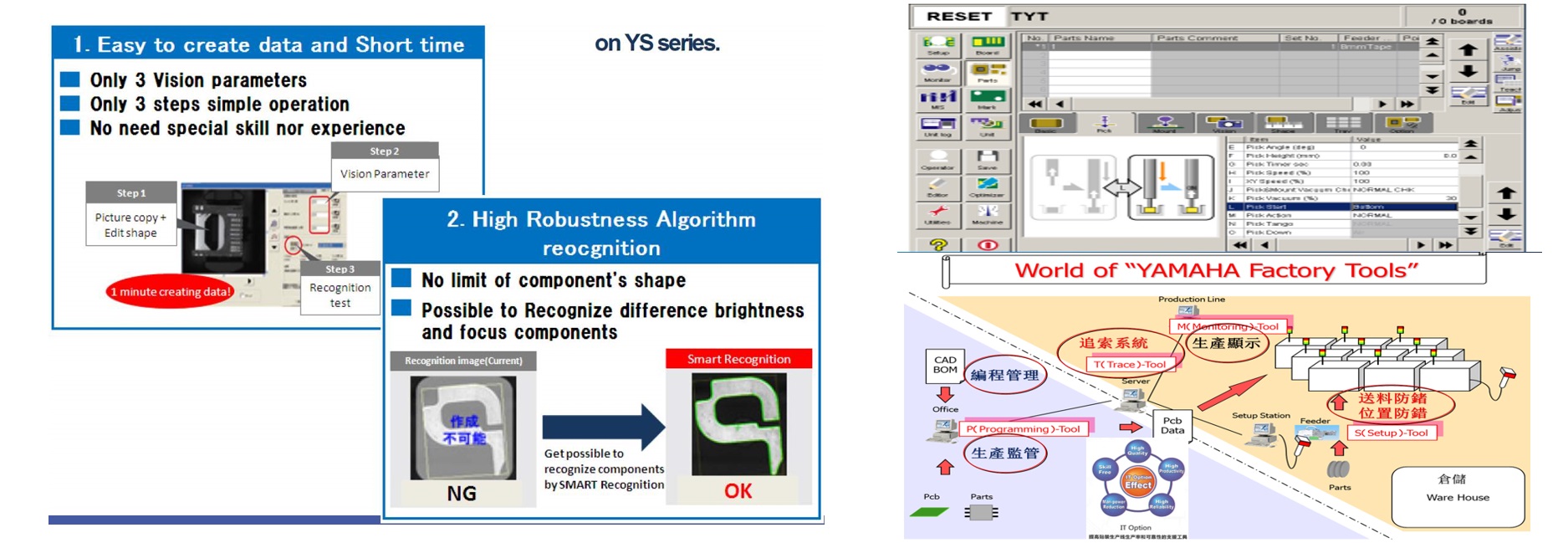

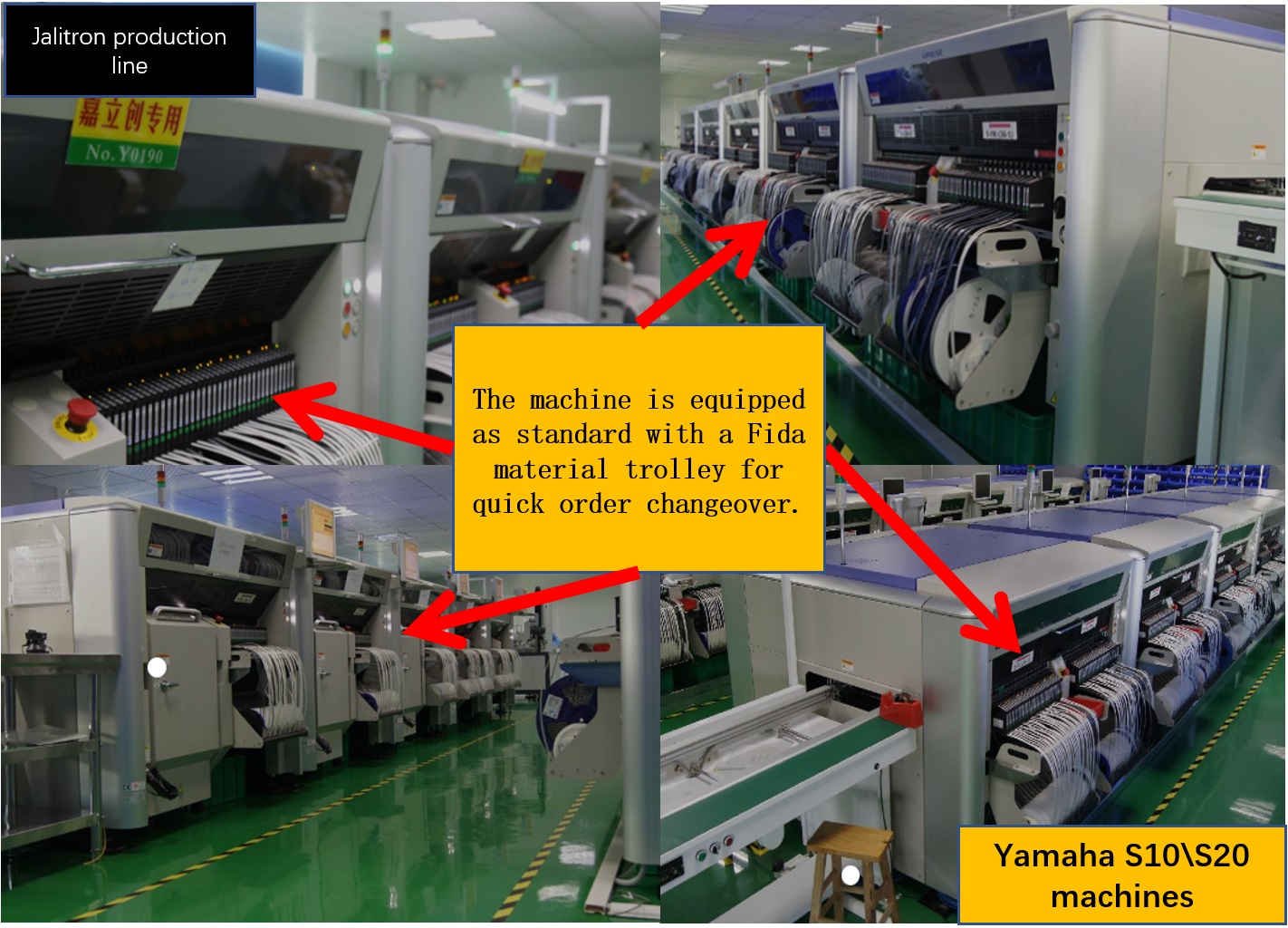

Our PCBA manufacturing services provide high-precision SMT assembly solutions, incorporating 2025 trends like AI-driven optimization and sustainable practices for efficient electronics production. Explore SMT equipment catalog.

PCBA Process Overview

PCBA manufacturing involves substrate prep, solder printing, high-speed placement, reflow, cleaning, and testing – ensuring high-density assemblies aligned with greener 2025 manufacturing.

SMT Line 2025

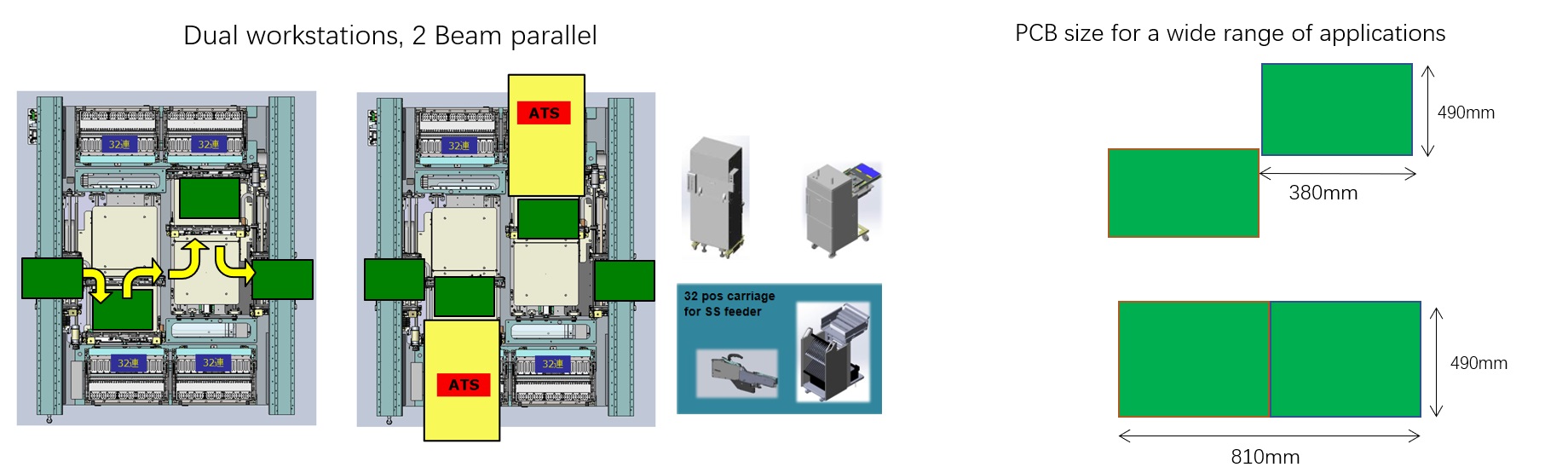

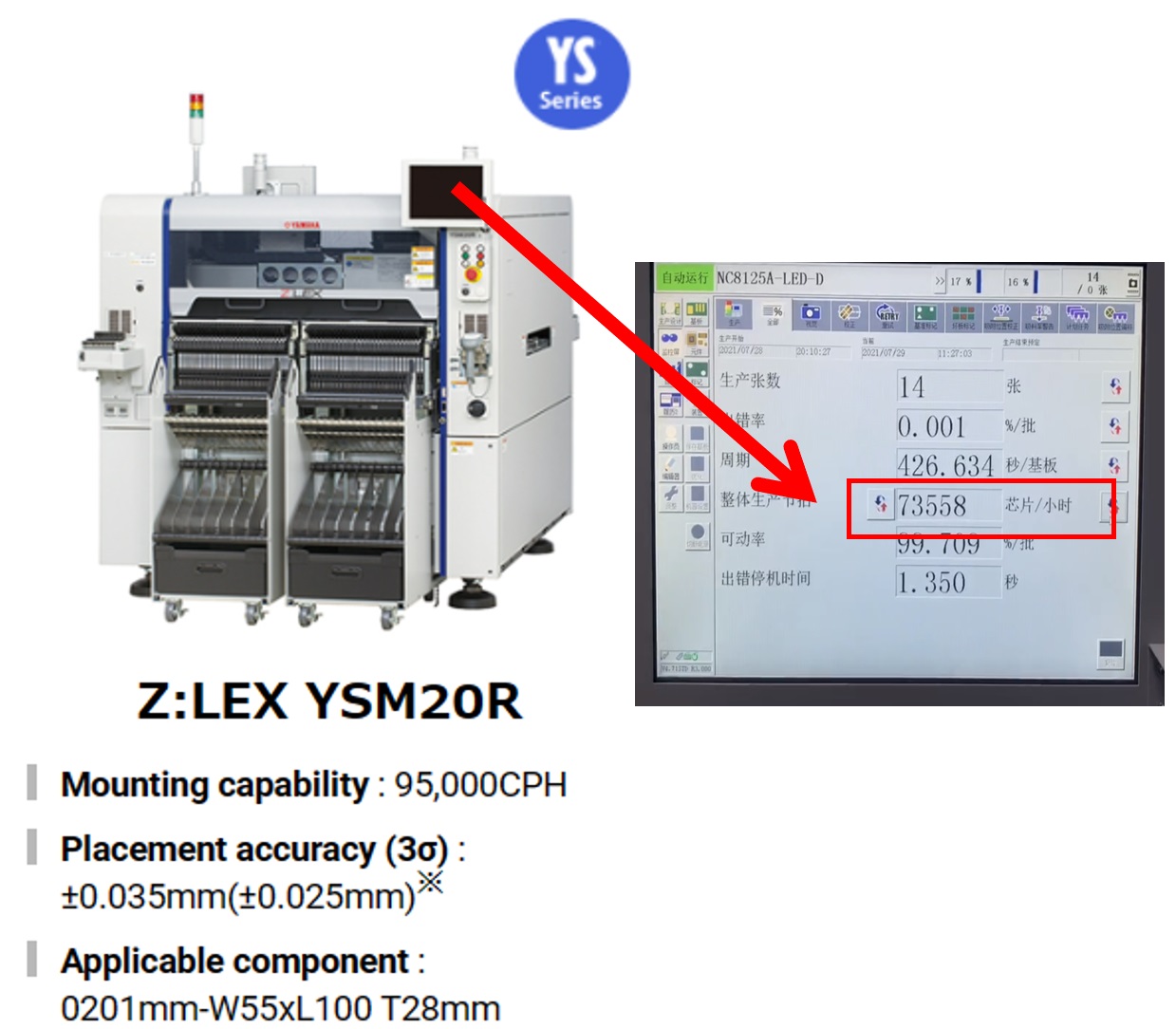

Yamaha YSM20R Specifications for PCBA

YSM20R 2024 Model

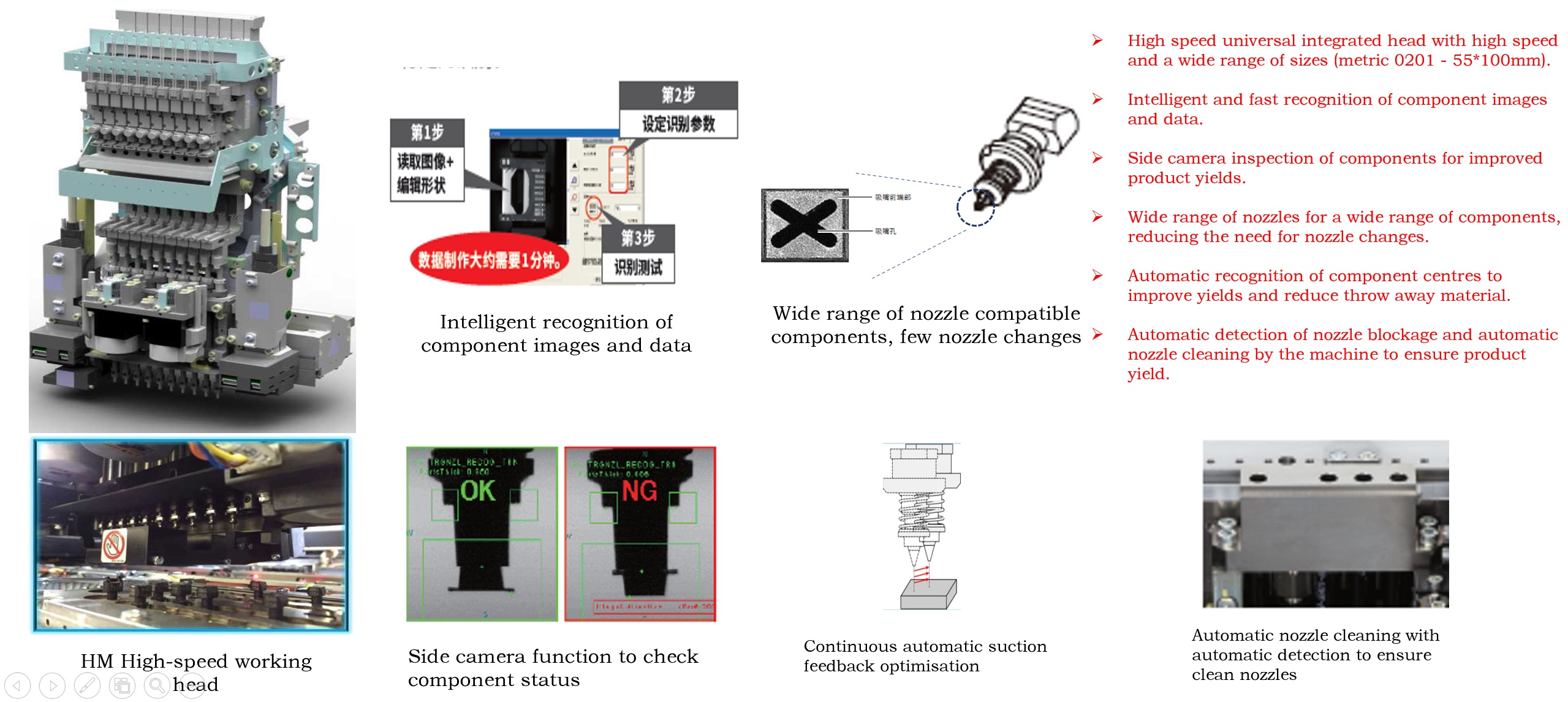

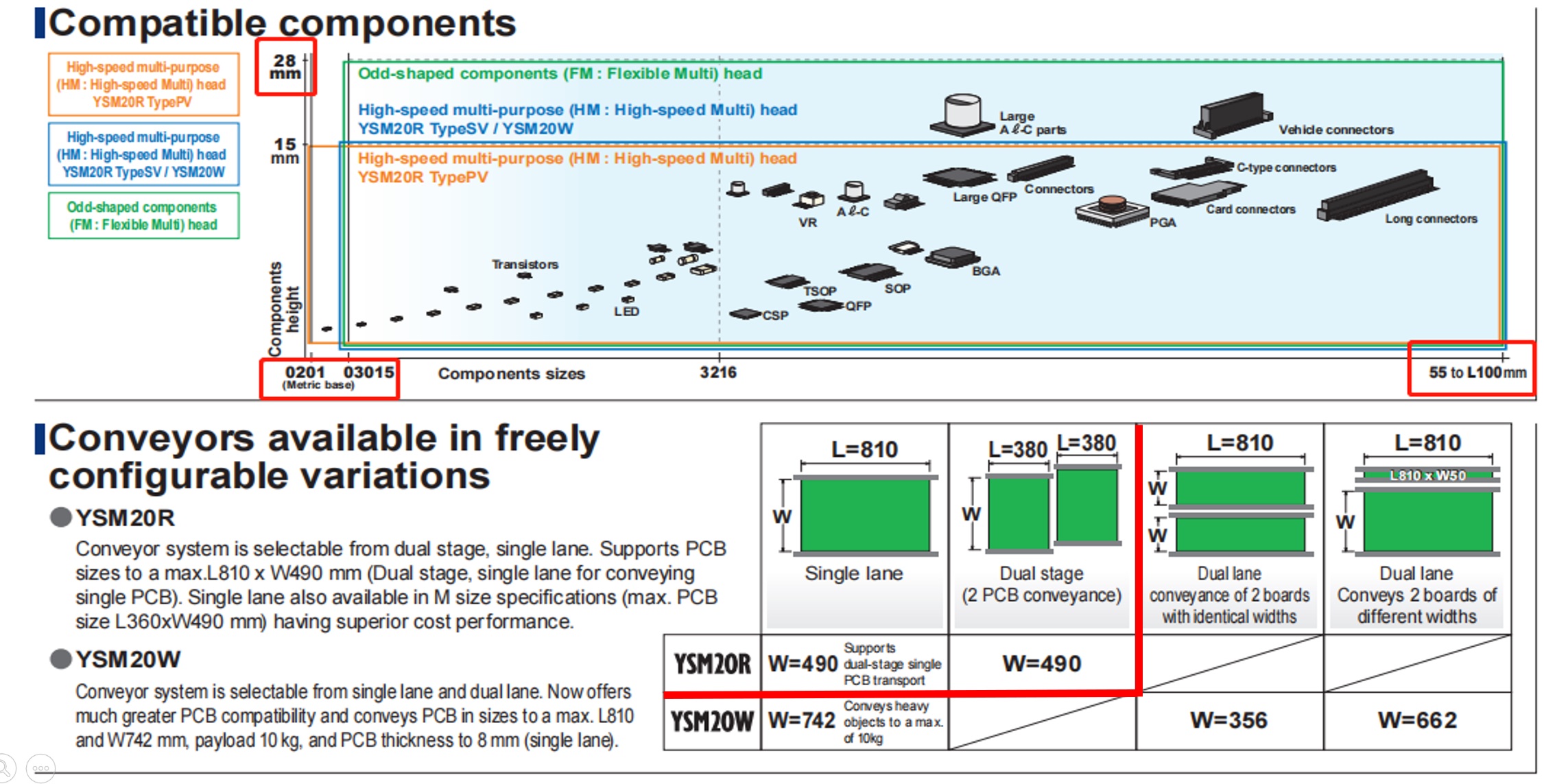

95,000 CPH, 0201-55x100mm components, ±35μm accuracy; updated for 2025 AI features. Power: 3-Phase AC; Dimensions: L1,374xW1,857xH1,445mm.

| Model | Speed (CPH) | Min Component | Max Component | Accuracy | 2025 Features |

|---|---|---|---|---|---|

| YSM20R | 95,000 | 0201 | 55x100mm | ±35μm | AI-optimization, sustainability |

| YSM20WR | 81,000 | 0201 | 55x100mm | ±35μm | Miniaturization support |

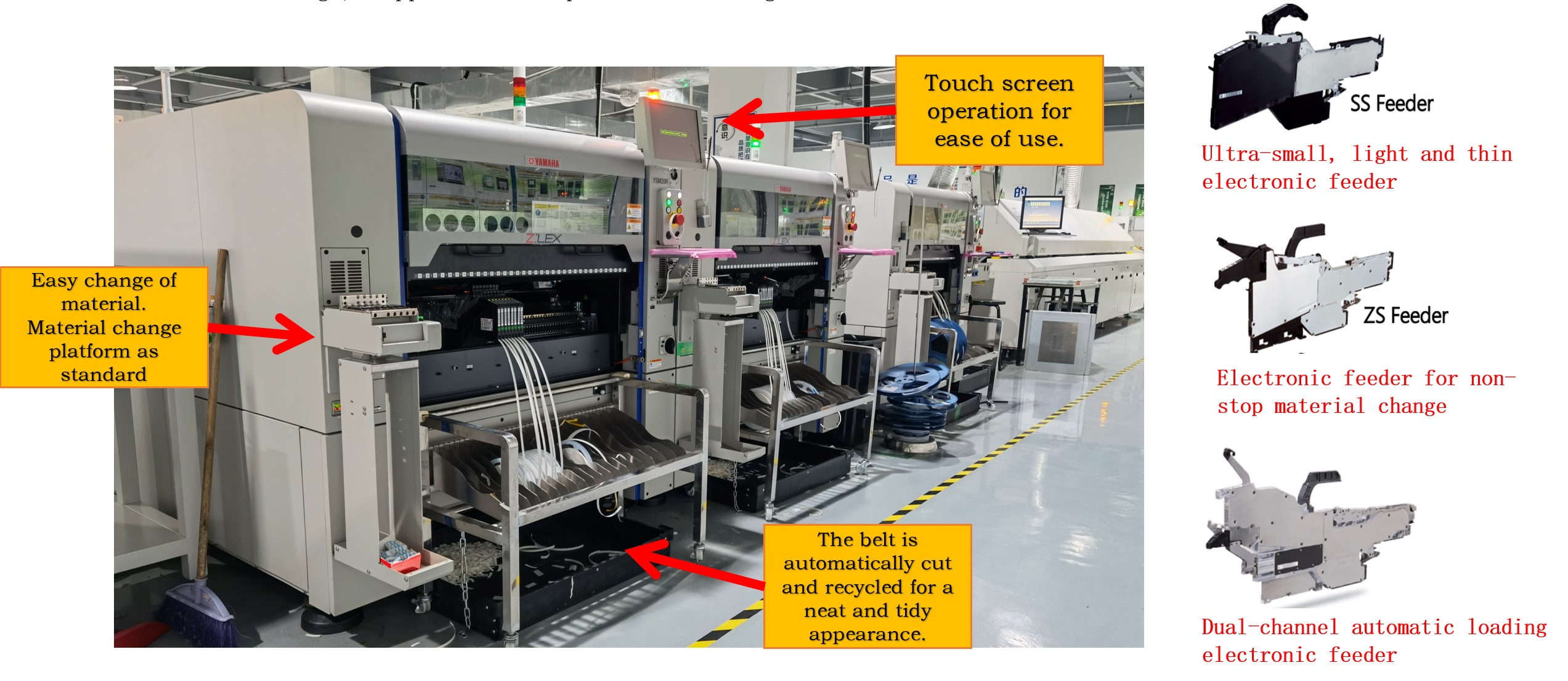

Advantages in SMT Assembly Solutions

Non-stop changes, magnetic heads for high efficiency; flexible for prototypes in 2025 trends.

Workflow 2025

Feeder Setup

Component Handling

Line Flexibility

Trial Production

Product Stations

Material Challenges

Workbench Setup

Head Change

High Yield

Non-Stop Ops

Precision Features

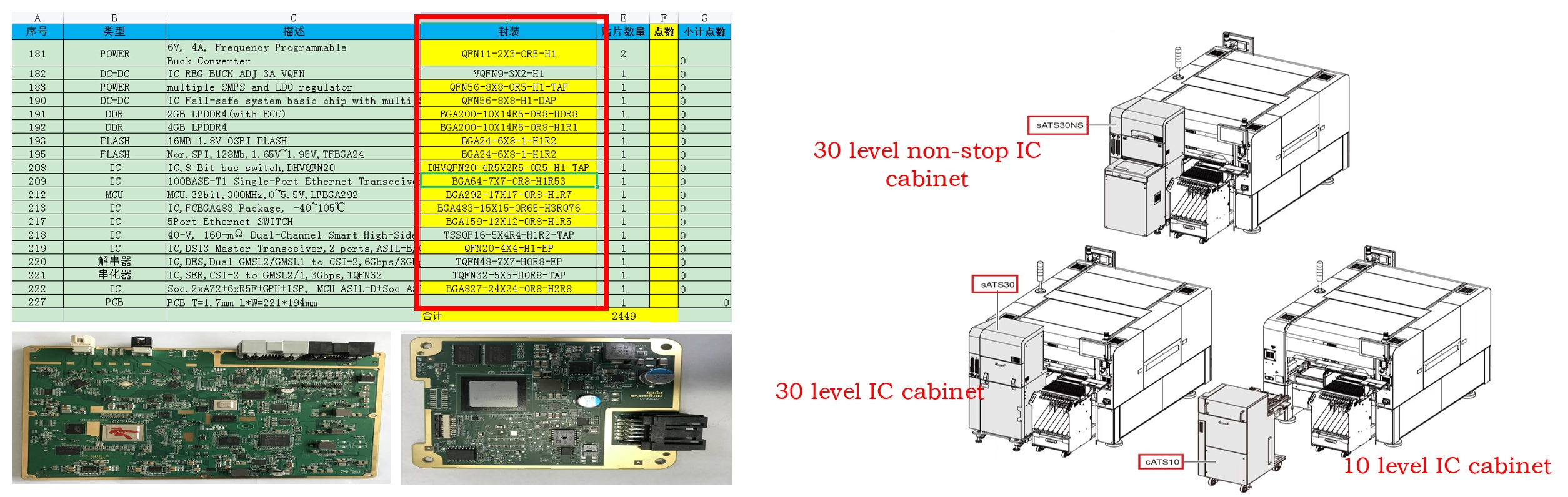

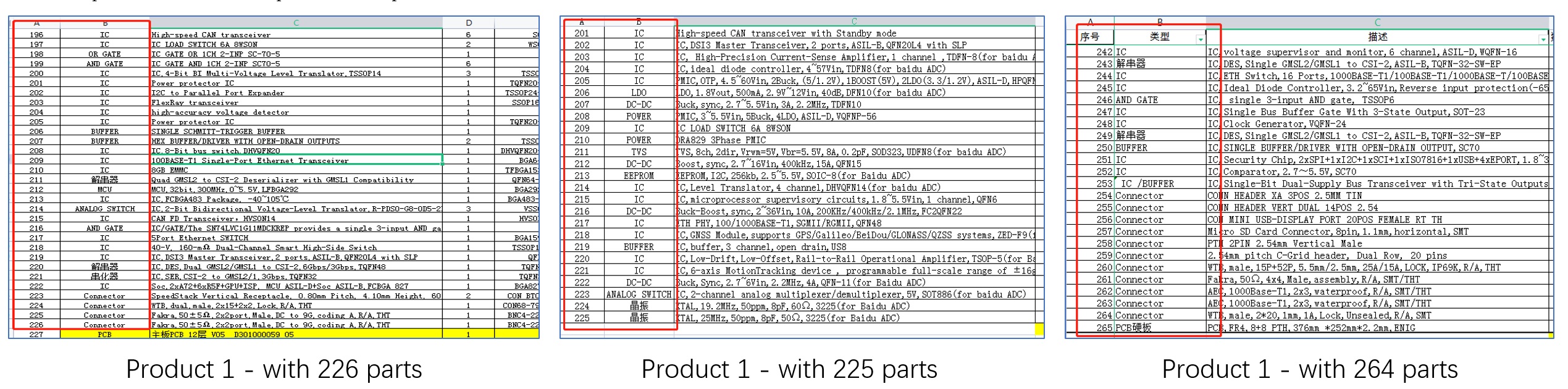

Industry Use Cases for PCBA Services

- Aerospace: Reliable PCBs for satellites in extreme conditions.

- Medical: High-density assemblies for 2025 scanning tech.

- Automotive: Control boards for efficient metering.

- Telecom: High-speed interconnects for communication.

- Industrial: Automation in soldering for factory efficiency.

Yamaha YSM20R Demo Video 2025

Downloadable Resources

Updated guides for 2025 PCBA projects.

FAQs

What is PCBA manufacturing?

PCBA manufacturing services involve assembling components on PCBs using SMT for high-precision electronics in 2025.

What are the specs of Yamaha YSM20R?

It offers 95,000 CPH speed, supports 0201 to 55x100mm components, with ±35μm accuracy for turnkey PCBA.

What industries use PCBA services?

Aerospace, medical, automotive, telecom, and industrial for reliable high-volume PCBA assemblies.

How do 2025 PCBA trends affect production?

Trends like AI-optimization, miniaturization, and sustainable practices enhance greener manufacturing.

Can I download the Yamaha YSM20R manual?

Yes, access the 2025 updated maintenance manual for detailed SMT assembly procedures.

Get Started

Contact for details on our solutions.

Messenger

Messenger

whatsapp

whatsapp

telegram

telegram