Product Number:LED lens Vibratory feeder SP-6

Product Usage:Lens feeders are used to automatically transport and position lenses to improve the efficiency and accuracy of the optical device assembly process.

Applicable Industries:Lens feeders are widely used in the following industries: 1. Optical device manufacturing 2. Electronic product production 3. Medical equipment manufacturing 4. Photographic equipment production 5. Laser equipment manufacturing 6. Automotive industry (especially optical systems related to autonomous driving) 7. Security monitoring

National Advisory Hotline:

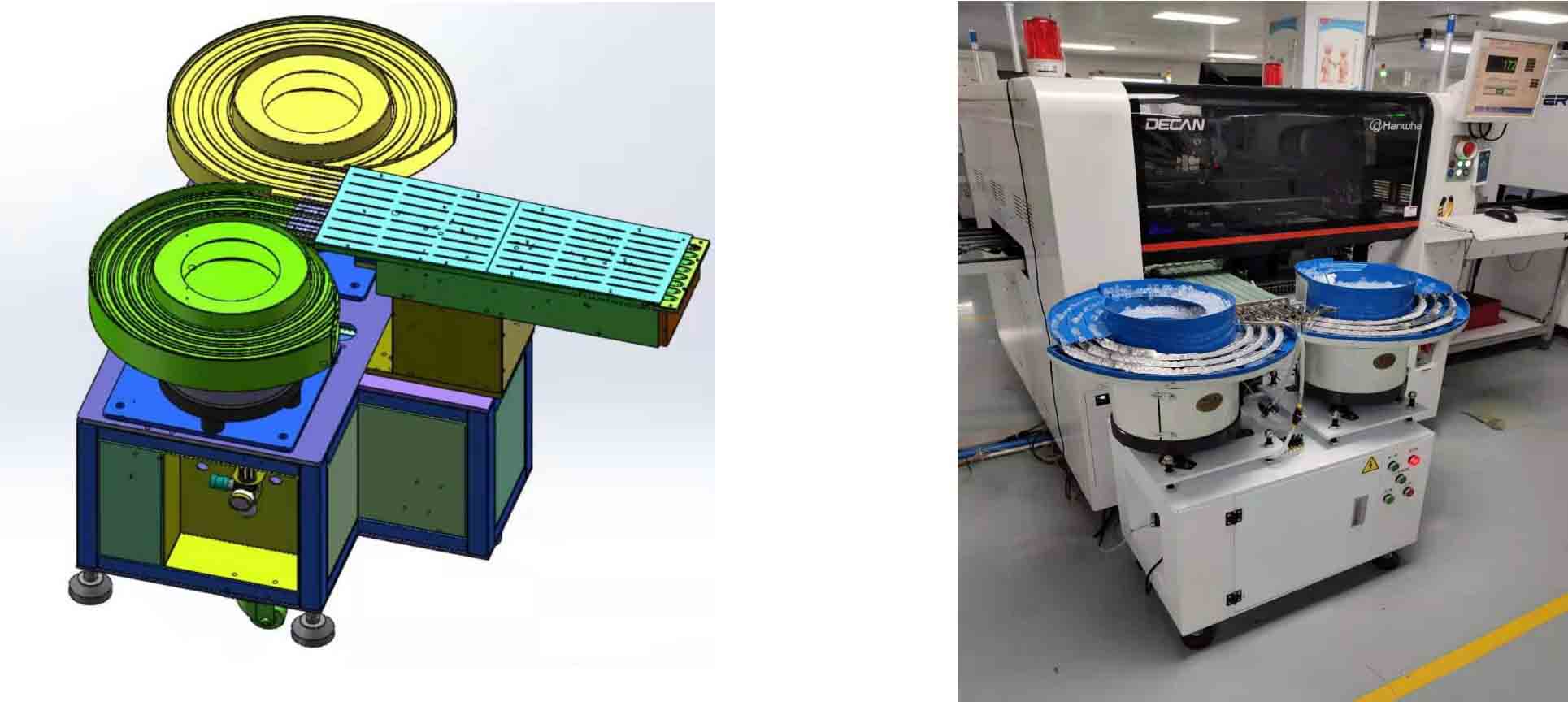

+86 18975335491Enhance your production line with the Lens Vibratory Bowl Feeder by JHIMS, a leading solution for automated lens feeding in SMT machines. Compatible with top brands such as YAMAHA YS12F, SAMSUNG SLM120S, Hanwha Decan L2, SM481, SM482, JUKI JX300, and JUKI 350, this precision feeding system is ideal for high-precision industries like optical device manufacturing and electronics assembly.

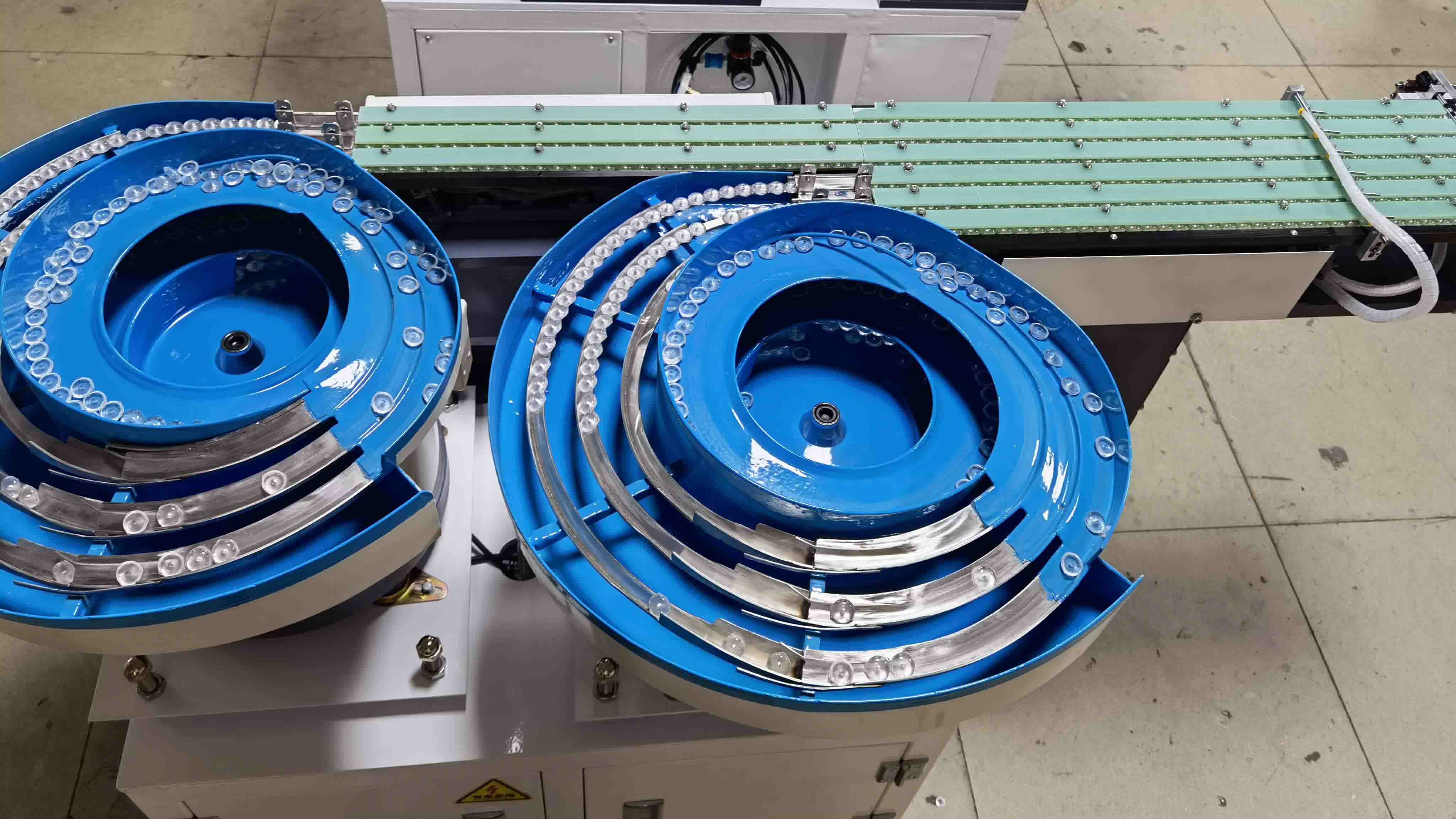

The Lens Vibratory Feeder is a specialized equipment designed to automate the transportation and alignment of lenses in SMT pick-and-place machines and robotic systems. Using controlled vibrations, it ensures lenses are precisely positioned for assembly, improving efficiency and quality in production processes.

| Vibrating Disc Feeder Specifications and Technical Parameters | ||

|---|---|---|

| Dimension | L x W x H | 1000x1000x950mm (Bowls are made by hand, some variation in size) |

| Weight | Double bowl: 190Kg | |

| Applicable Materials | Type of Material | Lens, electronic components, hardware, plastic parts, connectors |

| Material Size | 3x3mm - 50x50mm | |

| Material Weight | 10g - 300g | |

| Structural Parts | Feeding Method | Bulk material, vibratory loading |

| Feeding Bowls | Topping the left and right bowls | |

| Feeding Method | Vibration + blowing | |

| Positioning Method | Fibre optic sensing + PLC | |

| Fixing Method | Structural positioning | |

| Screening for Polarity | Can be set according to material | |

| Electrical Parts | Operating Voltage | 220V |

| Current | 3A/5A | |

| Air Pressure | 0.4-0.6Mpa | |

| Mode of Operation | Key operation | |

| Communication Methods | Support IO communication or control itself without communication | |

| Software Control | PLC-based development | |

| Drive Type | Coil drive | |

| Feeding Part | Feeding Speed | 0.8S |

| Speed Gears | Voltage and frequency regulation | |

| Feeding Accuracy | ±0.5mm | |

| Testing Records | Feed Test | Continuous feeding for 2 hours without abnormalities |

| Aging Test | 48 hours continuous operation without abnormalities | |

JHIMS offers custom vibratory feeders tailored to your needs. Submit your lens samples and pick-and-place machine details (e.g., Samsung SM481P or Hanwha Decan L2), and our engineers will craft a feeder optimized for your production line.

With expertise in vibratory feeding systems, JHIMS delivers reliable, high-quality solutions. Contact us to explore how our feeders can transform your SMT processes.