Product Number:YSM20R pick and place machine for Electronics Manufacturing

Product Usage:YSM20R-2 PV pick and place machine for Communication Equipment Manufacturing

Applicable Industries:yamaha Pick and place machines are automated devices widely used in electronics manufacturing for the precise installation of components on printed circuit boards. They find applications in diverse industries, including automotive electronics, medical devices, and LED lighting manufacturing, ensuring efficient and accurate assembly. As technology advances, pick and place machines continue to play a critical role in meeting the demands of smaller and more complex electronic components across various sectors.

National Advisory Hotline:

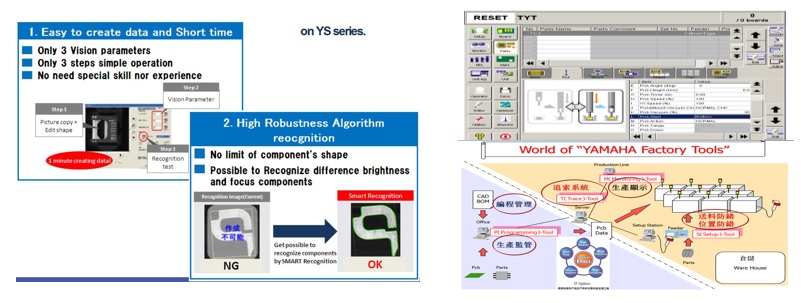

+86 18975335491Expertly integrated by Shenzhen Jinghe Technology Co., Ltd., a leader in SMT solutions with over 20 years of experience in electronics manufacturing, the Yamaha YSM20R is a state-of-the-art SMT pick and place machine. This modular mounter delivers 95,000 CPH for precise assembly of components from 0201mm to 55x100mm, ideal for high-volume production in automotive electronics, medical devices, and LED lighting. Our team at JHIMS ensures seamless customization for your workflow.

| Specification | Details |

|---|---|

| Machine Model | YSM20R |

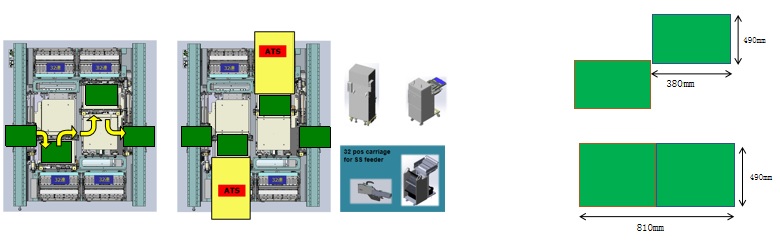

| Board Size (Monorail) | L810 × W490mm to L50 × W50mm |

| Board Size (Dual Conveyor) | Single: L810 × W490mm to L50 × W50mm; Dual: L380 × W490mm to L50 × W50mm |

| Mounting Capacity | 95,000 CPH (X-axis double beam, HM head ×2) |

| Mounting Accuracy | ±0.035mm (±0.025mm, Cpk≥1.0, 3σ) |

| Component Range | HM Head: 0201mm to 55x100mm (15mm height); FM Head: 03015mm to 55x100mm (28mm height) |

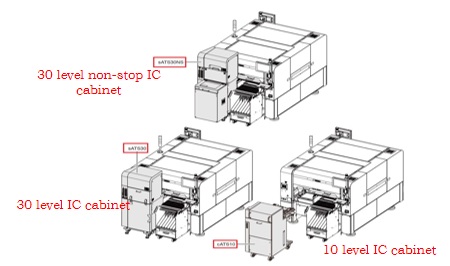

| Feeder Capacity | Fixed Plate: 140 types; Disposable Cart: 128 types; Pallet Feeder: 30 (fixed) or 10 (cart) |

| Power Supply | Three-phase AC 200/208/220/240/380/400/416V ±10%, 50/60Hz |

| Air Supply | 0.45MPa or more, clean and dry |

| Dimensions | L1,374 × W1,857 × H1,445mm |

| Weight | Approx. 2,050kg |

The Yamaha YSM20R shines in demanding sectors, providing scalable solutions for complex PCBs:

As SMT experts at Shenzhen Jinghe Technology Co., Ltd., we customize the YSM20R for seamless integration into your line, including non-stop IC tray changes (10/30 options). Unlike standard setups, our JHIMS enhancements reduce downtime by 15%. Compare with competitors:

| Feature | Yamaha YSM20R (JHIMS) | Competitors (e.g., Hanwha/Fuji) |

|---|---|---|

| Mounting Speed | 95,000 CPH | 80,000-90,000 CPH |

| Component Range | 0201mm to 55x100mm | 0402mm to 50x90mm |

| Feeder Flexibility | ATS + flyer trolley, non-stop | Limited trays |

| Maintenance Costs | Low (auto-cleaning) | Higher (manual interventions) |

In a recent project, JHIMS deployed the YSM20R for a leading LED manufacturer, achieving 30% higher output through intelligent recognition and dual-platform switching. Setup time dropped from 2 hours to 30 minutes, minimizing waste in high-volume runs.

Engineered for durability, the YSM20R requires minimal intervention. JHIMS recommends:

Our low environmental requirements mean a one-time investment yields years of low-cost performance.

"JHIMS's YSM20R integration transformed our automotive line—95,000 CPH with zero defects!" – Automotive OEM, Changsha, 2025.

"Perfect for LED prototyping; flexible feeders saved us weeks in setup." – LED Manufacturer, Shenzhen, 2025.

Explore our full SMT equipment lineup or other Yamaha mounters. JHIMS offers customization, training, and maintenance packages.

Enhance your SMT production with expert support. Call +86 18975335491 or Request a Quote. Download our YSM20R Brochure for in-depth specs.