Product Number:GSA

Product Usage:PCB Stencil Printe

Applicable Industries:SMT automatic solder printers are widely used in electronics manufacturing, communication equipment, computer hardware, consumer electronics, automotive electronics, medical electronics, industrial automation and aerospace industries. The technology enables high-density, high-performance electronic device manufacturing in the production process, including precise solder printing of chips, resistors, capacitors and other components on PCBs to meet the requirements of modern electronic products for miniaturization, lightweight and high reliability.

National Advisory Hotline:

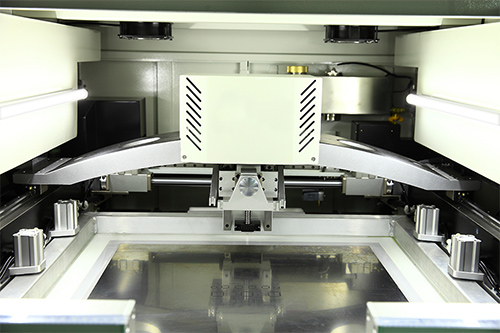

+86 18975335491The JHIMS GSA Solder Paste Printer is a fully automatic solution for high-precision SMT assembly. With advanced features like an automatic cleaning system and dual motorized printheads, it ensures accurate solder paste application for PCBs.

The JHIMS GSA Solder Paste Printer is designed for electronics manufacturers seeking precision and efficiency in surface-mount technology (SMT) production. Ideal for PCB assembly, it offers a robust feature set tailored to modern manufacturing needs.

The JHIMS GSA supports various screen template sizes, offering wide applicability. Its stencil positioning system reduces product switchover time, boosting efficiency in SMT production.

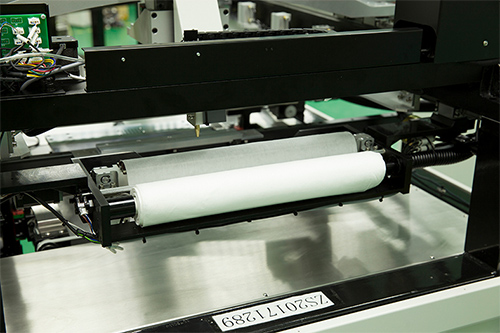

Featuring dry, wet, and vacuum cleaning modes, the JHIMS GSA’s cleaning system is programmable or manual. It ensures uniform spray, efficient material use, and thorough stencil cleaning with a specialized fan.

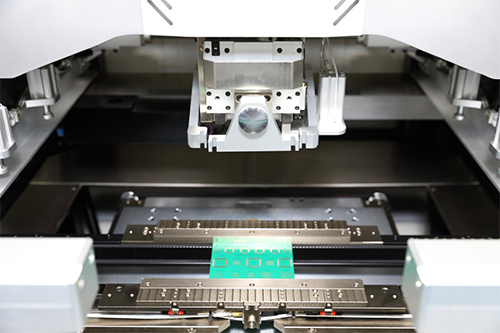

The unique conveyor system prevents PCB jams and falls, with precise speed and position control. Flexible side clamping and vacuum adsorption ensure flat contact with the stencil.

With a three-axis linkage system, the JHIMS GSA quickly adjusts PCB thickness and offsets (X, Y, R angles) using system parameters and marking points for seamless calibration.

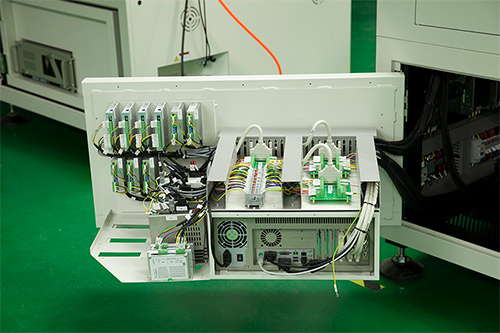

An integrated modular design simplifies operation, making the JHIMS GSA user-friendly for production staff.

| Category | Parameter | Value |

|---|---|---|

| Screen Frames | Min Size | 370 x 370 mm |

| Max Size | 737 x 737 mm | |

| Thickness | 25–40 mm | |

| PCB Min Size | 50 x 50 mm | |

| PCB Max Size | 400 x 340 mm | |

| PCB Thickness | 0.4–6 mm | |

| PCB Warpage | <1% | |

| Transport Height | 900 ± 40 mm | |

| Transport Direction | Left-Right; Right-Left; Left-Left; Right-Right | |

| Transport Speed | Max 1500 mm/s (Programmable) | |

| Board Location | Support System | Magnetic Pin/Up-down table adjusted/support block by hand |

| Clamping System | Side clamping, vacuum nozzle | |

| Print Head | Two independent motorized printheads | |

| Squeegee Speed | 6–200 mm/sec | |

| Squeegee Pressure | 0–15 Kg | |

| Squeegee Angle | 60°/55°/45° | |

| Squeegee Type | Stainless steel (Standard), plastic | |

| Stencil Separation Speed | 0.1–20 mm/sec (Programmable) | |

| Cleaning System | Dry, Wet, Vacuum (Programmable) | |

| Table Adjustment Ranges | X: ±10 mm; Y: ±10 mm; θ: ±2° | |

| Table Adjustment Control | Linear motor control | |

| Repeat Position Accuracy | ±0.01 mm | |

| Printing Accuracy | ±0.025 mm | |

| Cycle Time | <7s (Excluding Printing & Cleaning) | |

| Product Changeover | <5 Min | |

| Air Required | 4.5–6 Kg/cm² | |

| Power Input | AC: 220 ± 10%, 50/60HZ, 1Φ, 3KW | |

| Control Method | PC Control | |

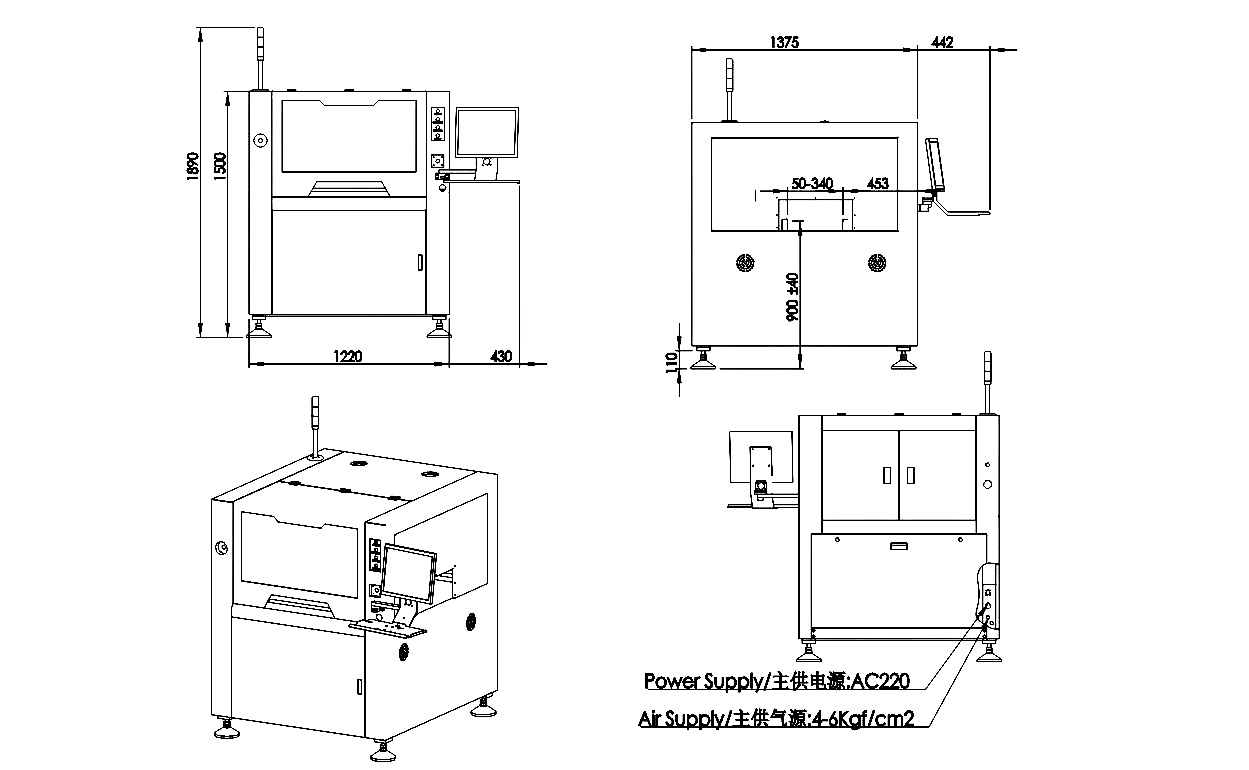

| Machine Dimensions | 1220(L) x 1355(W) x 1500(H) mm | |

| Machine Weight | Approx. 1000 Kg | |

Contact us today for a quote or demo!

Contact us at +86 18975335491 or info@jhims.com